Brief Introduction

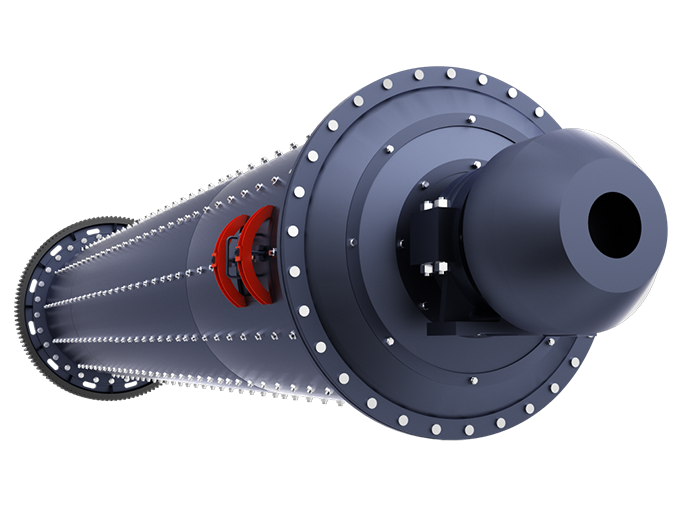

The raw material mill is the key equipment for the material to be crushed again after being crushed by the crusher. After long-term exploration and summarization in the design and production process, our company has formed a series of products with different specifications, satisfying the functional requirements of different materials and rich in variety, especially in the grinding of slag, cement, and other materials.