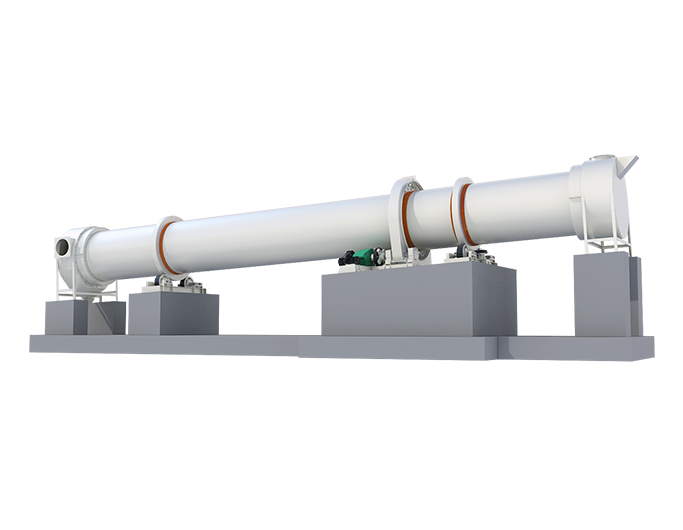

Brief Introduction

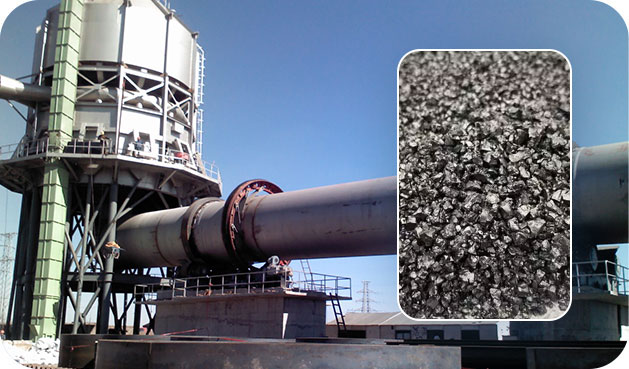

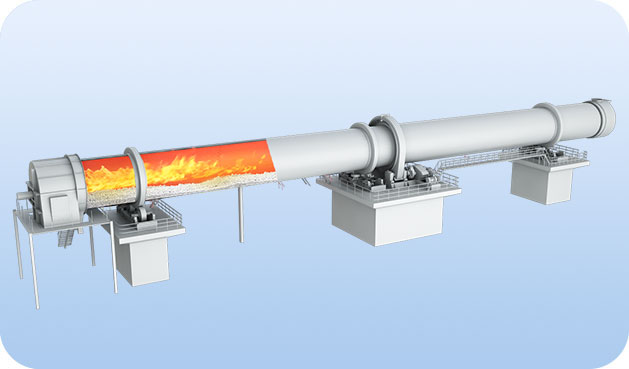

The cement kiln is mainly used for calcining of cement clinker. There are dry and wet types. The metallurgy industry and ironworks for lean iron ore, chromium ore, and ferronickel ore calcimine. Rotary kiln is used for calcimine of high aluminum vandal ochre in the refractory material industry: calcimine of calotte and aluminum hydroxide in aluminum manufacturer, claiming of chrome sand ore and chrome powder ore in a chemical plant. The lime kiln (active lime kiln) is used for roasting the active lime which is used in steel works and ferroalloy works, and calcined dolomite.