Brief Introduction

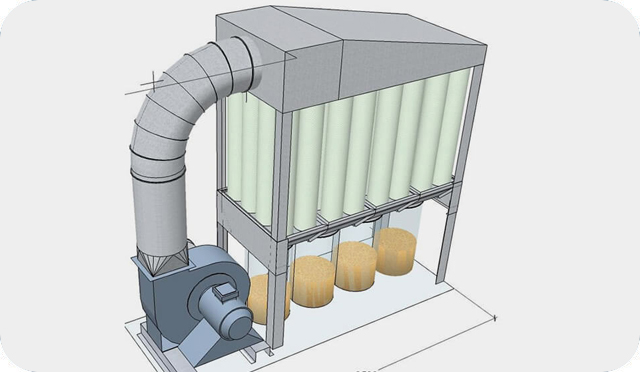

PPC type gas box pulse bag type dust collector is widely used in building materials, cement, metallurgy, machinery, chemical and refractory industries. It is especially suitable for dust collection systems (or dust removal systems) such as crushing, library top, roofing, clinker coolers and various mills in cement plants. It has strong applicability, which is mainly suitable for dust collection of dusting points from the crusher, cement mill, raw material grinding, dust collector, powdering machine, conveyor, storage top and bottom.