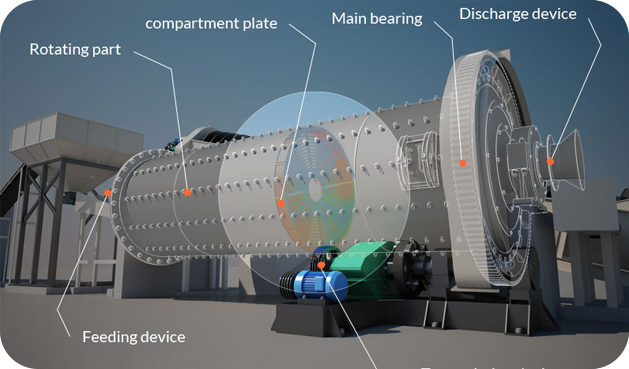

Brief Introduction

Coal mill is one of the four auxiliary engines of a thermal power station. It is the main equipment of the pulverized coal preparation system and mainly used for grinding coal of multiple hardness. It is also suitable for coal and ore raw materials in cement, metallurgy and chemical industries. The special steel ball coal mill for power plants is a new type of equipment, which is widely used in thermal power plant equipment.