Brief Introduction

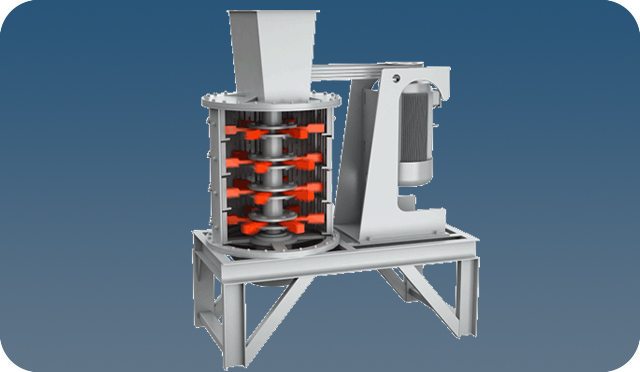

The compound crusher is also named combination crusher, and is one of the commonly used equipment in the crushing production line and the sand making production line. This series of crusher is a new product based on our company's PEL vertical compound crusher and optimized with domestic and foreign fine crushing technology. Its performance has reached the domestic advanced level. It is mainly for all kinds of ore with compressive strength not exceeding 200MPa and water content less than 15%.