Brief Introduction

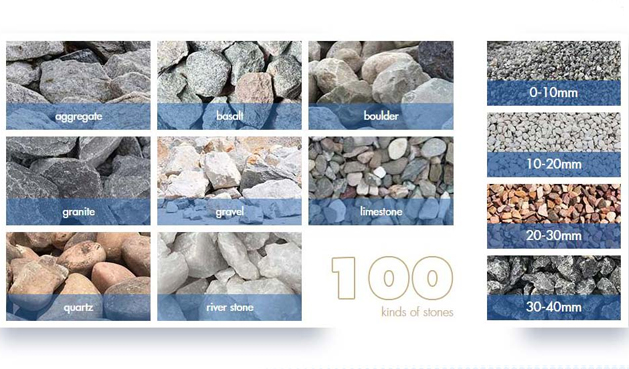

Jaw crusher is one kind of the best-selling crusher machine for stones and ores. Due to its high performance and competitive price, it is widely used for processing granite, limestone, quarry stones, gravel, basalt, aggregate, gold ore, iron ore, concrete, etc.

With the unique structure and wide throughput range, jaw crusher can be used for primary and fine crushing of over 120 kinds of stones and ores in mining, quarry, construction and other fields.