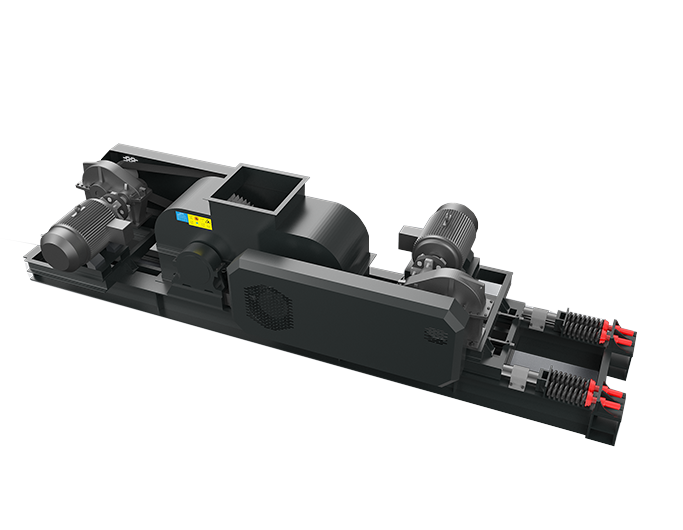

Brief Introduction

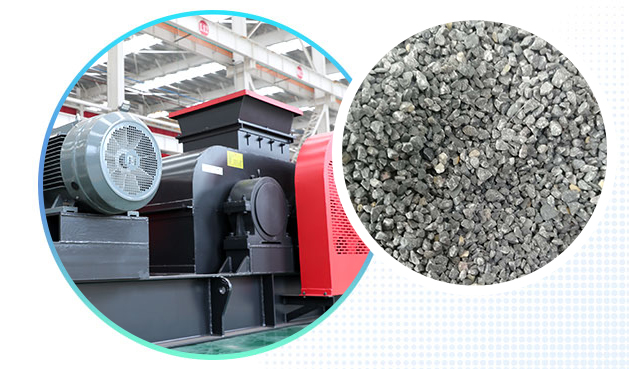

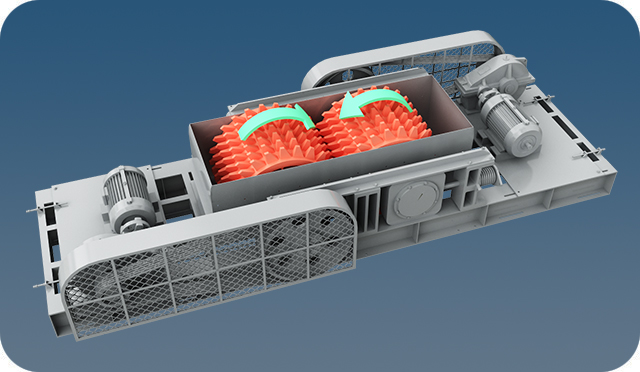

The toothed roller crusher is suitable for coal, metallurgy, mining, chemical, building materials and other industries, and is more suitable for the crushing of raw coal (including vermiculite) in large coal mines or coal preparation plants. It has strong crushing force. The motor and the reducer are connected by a limit type hydraulic coupling to prevent the power overload and have the sensor overload protection, which is safe and reliable.