Compound Cone Crusher

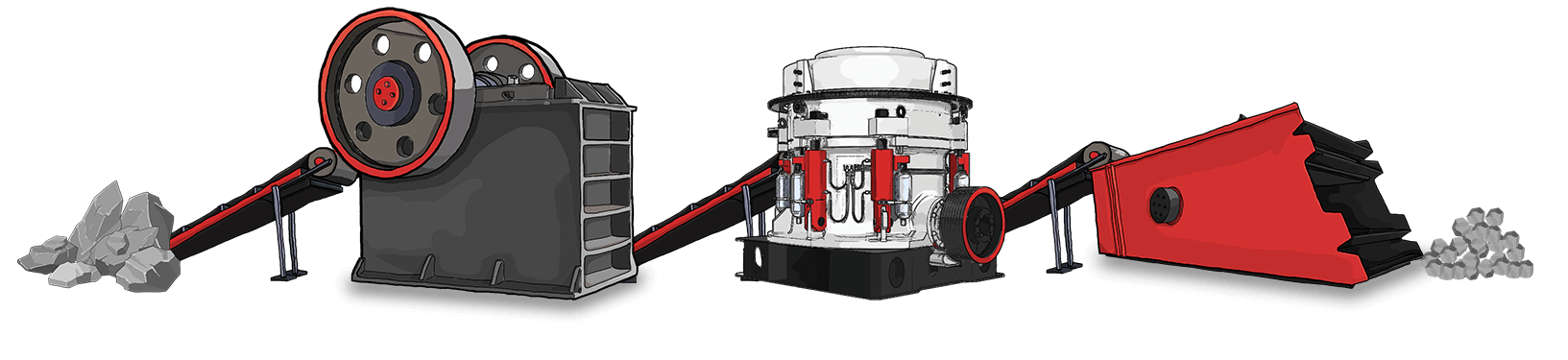

Compound cone crushers are widely used in metallurgy, building materials, road construction, chemical and silicate industries. It is suitable for all kinds of ore and rock with medium and medium hardness. The machine has the characteristics of large crushing ratio, high efficiency, high processing capacity, low operating cost, and convenient adjustment.

Brief In Compound Cone Crusher

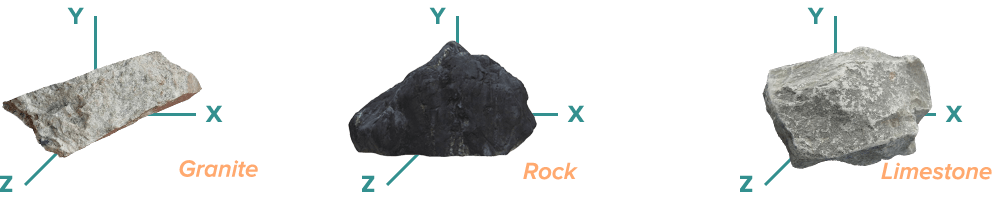

Compound cone crusher is suitable for various ores and rocks such as river pebble, granite, dolomite, basalt, limestone, quartz, diabase, iron ore, gold, copper, etc. Due to the reasonable material selection and structural design, the service life is long, and the granularity of the crushed product is uniform, which reduces the cyclic load.

In the medium and large size crushers, the hydraulic clearing system is adopted to reduce the downtime, and there are many types of crushing chambers for each specification. Users can select different cavity types according to different needs. The machine is sealed with grease, which avoids the defects of easy clogging of water supply and drainage system and the defects of easy mixing of water and oil. The spring safety system is an overload protection device, which can allow foreign bodies and iron blocks to pass through the crushing chamber without damaging the crusher. The machine is divided into standard type and short head type. Generally speaking, the standard type feeding size is large, and the discharge size is also coarse. The short head type crusher cone is steep, the feeding size is small, and it is favorable for producing fine grain material. So the standard type is generally used for coarse and medium crushing, and the short type is used for medium and fine crushing.