Brief Introduction

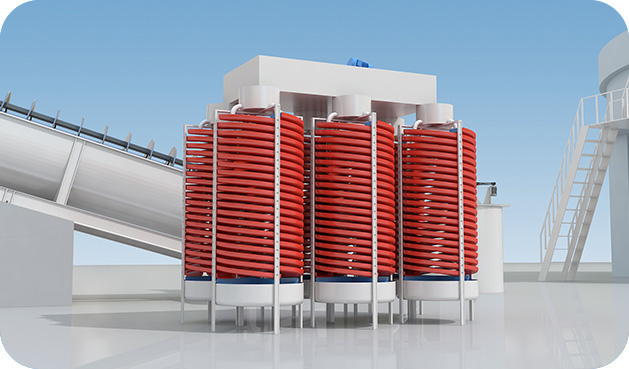

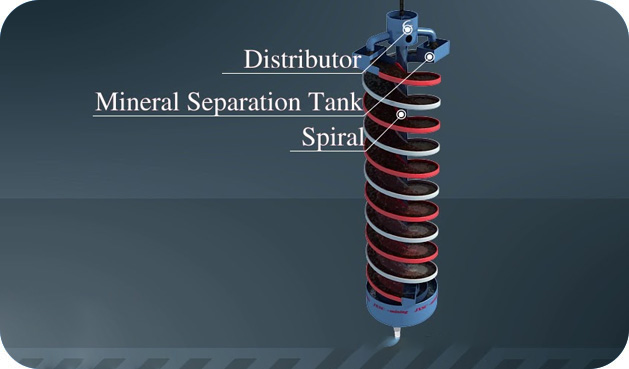

Spiral concentrator, also known as mineral spiral separator, spiral concentrator, spiral concentrator, gravity spiral concentrator, is suitable for recycling various fine minerals, improving resource utilization, and rationally and effectively developing and utilizing mineral resources.

The spiral concentrator is suitable for sorting fine iron ore, copper ore, chromite, aluminum ore, pyrrhotite, hematite, tungsten ore, tin ore, gold ore, and other non-ferrous metals and rare metals with different specific gravity. The spiral concentrators produced by FTM are divided into four types: DL2000, DL1500, LL1200 and LL900. You can purchase them according to your actual needs.