Brief Introduction

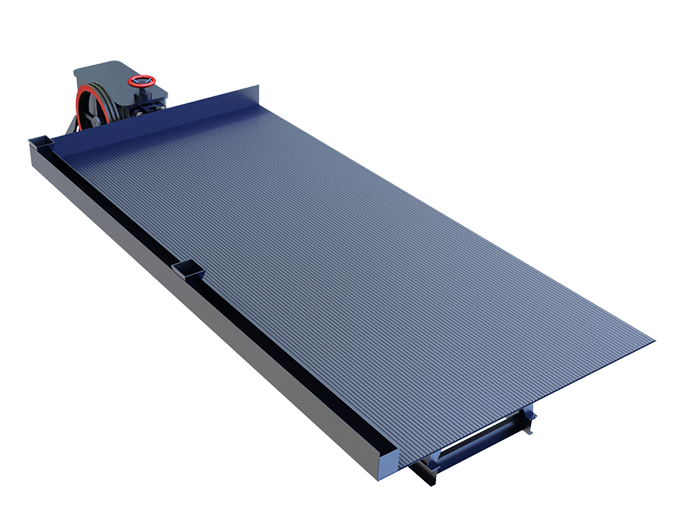

A gold shaking table (also known as gold gravity separation) is a commonly used beneficiation device for sorting fine-grained materials in minerals according to their density. The sorting precision is high.

The shaking table comprises eight parts, including the bed head, motor, slope regulator, bed surface, mine tank, water tank, rifling bar and lubrication system. The longitudinal reciprocating motion of the bed surface is realized through the crank-link transmission mechanism.