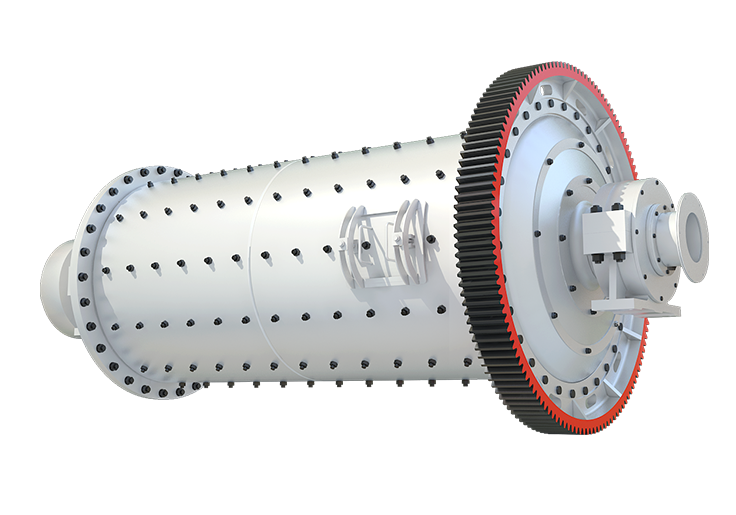

Brief Introduction

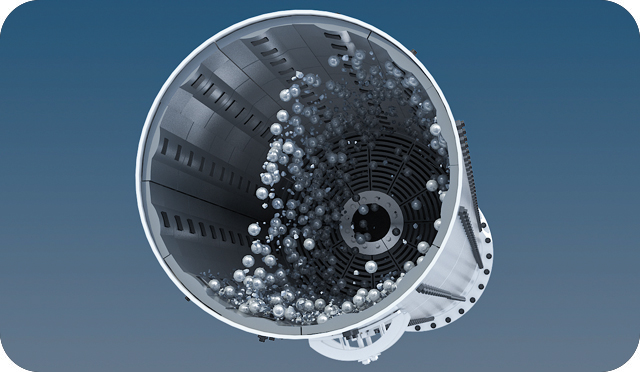

Rod mill is the key equipment for grinding after materials are crushed at crushing plant. Rod mill is an efficient crushing machine for grinding various materials into powder. Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills. Rod mills crush generally coarser than those produced in Ball mill, and rod mills are well suited to handle coarser feed and to control the bigger size of the product.