Brief Introduction

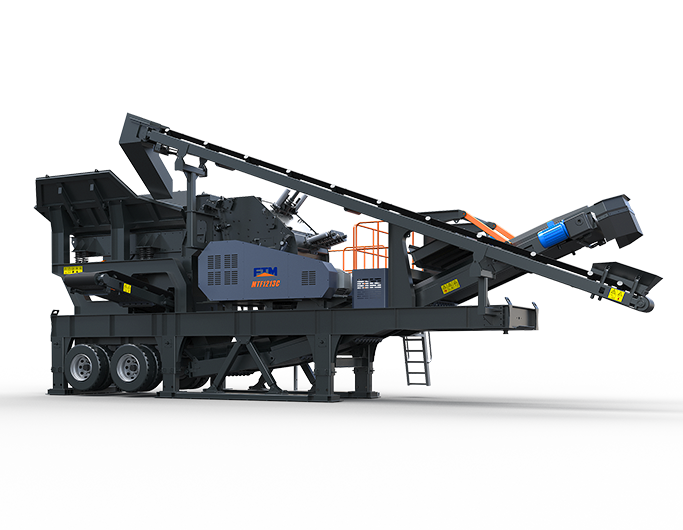

The wheeled mobile impact crusher is mainly composed of a feeder, a jaw crusher, a belt conveyor and a vibrating screen. It belongs to the medium-fine crushing and screening series. The crushing station integrates crushing and screening into one part, has higher crushing efficiency, stronger function, and excellent quality of crushed products, and can meet the requirements of crushing and screening of medium and fine materials in a wide range.