Brief Introduction

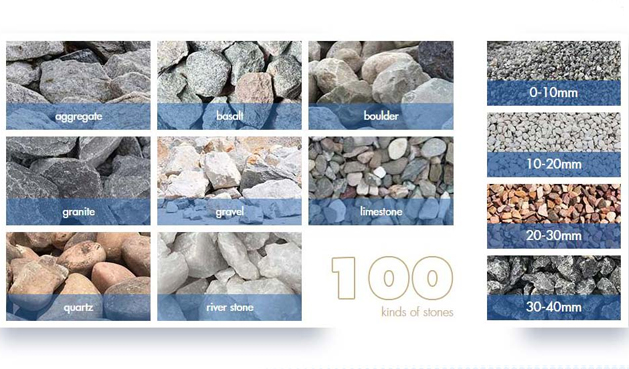

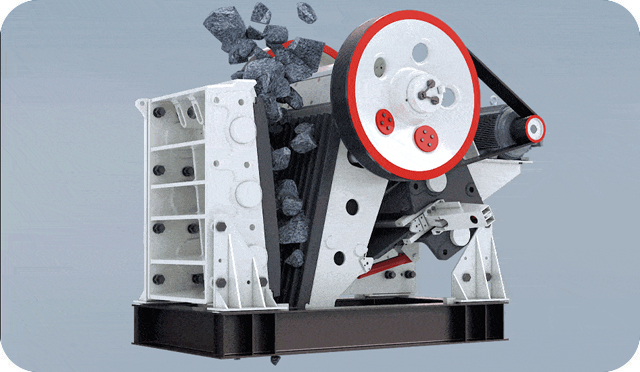

Mining crushers can be used for coarse crushing in primary crushing stage, medium crushing in secondary crushing stage, fine crushing in tertiary crushing stage, sand making, etc. Different types have different output sizes, different feeding sizes and different processing capacities. It is widely used in mining, smelting, road, railway, building materials, construction, chemical industry and other fields.