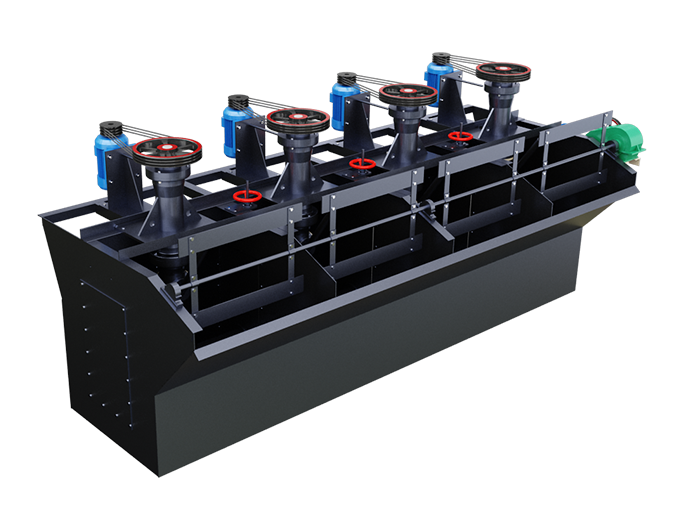

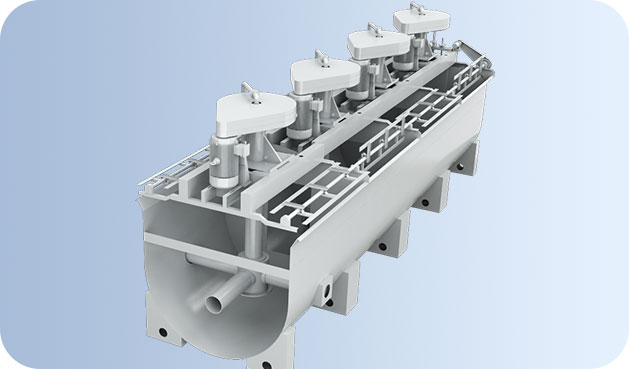

Brief Introduction

Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water.

Froth flotation can selectively separate core minerals from middlings or tailings, making them high-grade mineral concentrate. Since froth flotation can separate minerals from already processed concentrates besides the primary ore, it is considered to have high efficiency in recovering minerals.