Brief Introduction

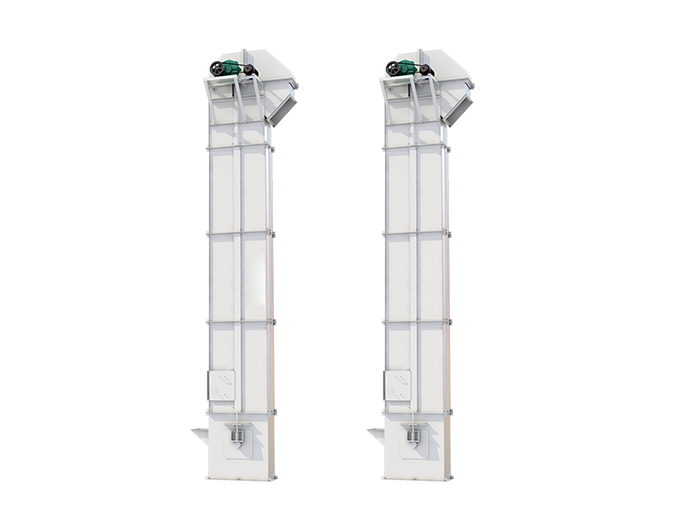

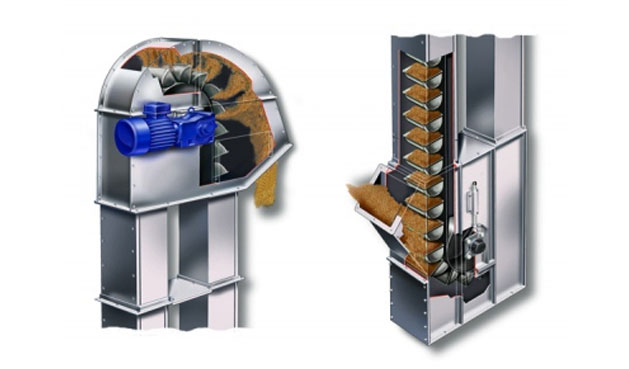

The bucket elevator is suitable for vertical transport of powdery, granular and small block materials. It has the characteristics of simple structure, stable operation, high lifting height, and long lifespan. According to the material characteristics and the conditions of use, the bucket elevator is divided into the ring chain bucket elevator, the wire belt bucket elevator and the plate chain bucket elevator.