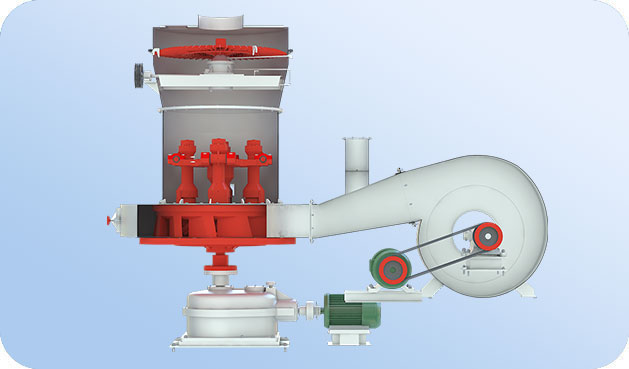

Brief Introduction

High strength grinding mill is a new type of grinding mill introduced by FTM. High strength grinding mill is suitable for crushing barite, limestone, ceramics and slag, with a Mohs hardness of not more than 9.3, and a humidity of 6% or less in the fine powder processing of non-flammable and explosive mines, metallurgy, chemicals, building materials, and other industries. The finished product size is adjusted in the range of 80-425 mesh (the finest 1000 mesh). A 30-80 mesh coarse powder can be produced by adding special equipment inside the machine.

Currently, hot sale types in the market are high strength 96, high strength 95, high strength 93, high strength 86, and high strength 83.