Brief Introduction

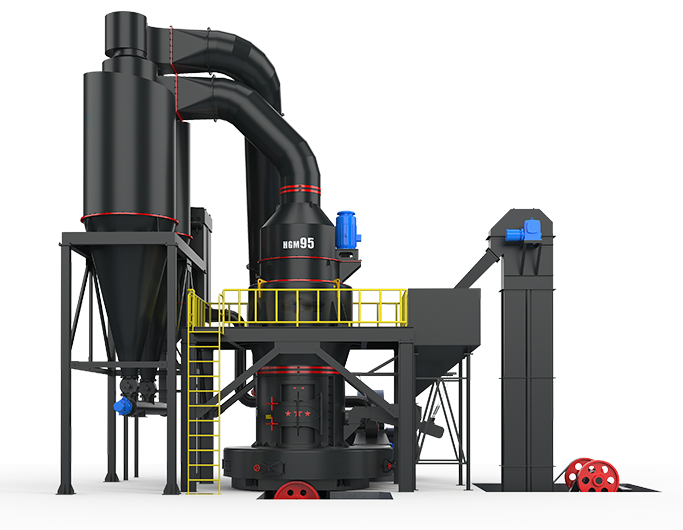

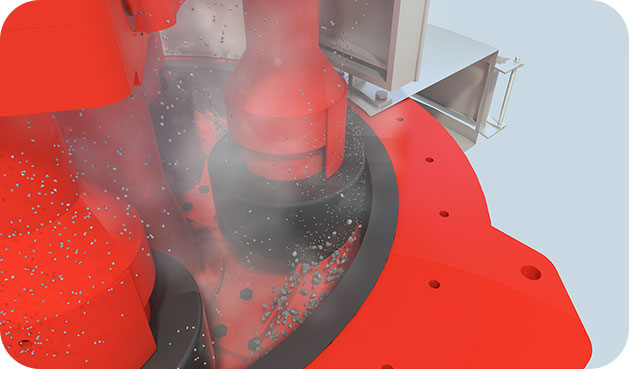

HGM Ultrafine Grinding Mill is an upgraded version of Raymond Mill. The basic structure consists of the main unit, fan, powder separator, cyclone dust collector, dust collector, pipe device, and motor. The main unit consists of a frame, an air inlet volute, a shovel, a grinding roller, a grinding ring, and a cover. Ancillary equipment also includes jaw crusher, bucket elevator, electromagnetic vibration feeder (small size, can be sealed, can be fed continuously and evenly), silo, power distribution cabinet (control the entire line), etc.

This machine can be used to process all kinds of non-flammable and non-explosive mineral materials with Mosh Hardness below 9.3 and humidity below 7%.The fineness of finished products can be adjusted between 0.18mm and 0.01mm (80 mesh-1250 mesh), and some materials can reach more than 2000 mesh.