NEWS

The annual output of 10 million tons of river pebble crushing production line

By: Fote MachineryMarch 16th,2019

With the rapid development of Chinese economy, the sand and gravel aggregate industry has achieved a series of high-profile achievements. But the long-standing and extensive development model has left a lot of historical problems, such as irrational industrial structure, ecological environmental pollution, and lagging industrial technology development. The negative impact of these problems on social and economic development is increasingly apparent. Adjusting the industrial structure, accelerating the transformation and protecting the ecology have become the irreversible main direction of the sand and gravel aggregate industry.

In order to expand the scale of sandstone production and conform to the development mode of green environmental protection, a green building materials company in China hopes to build a domestic advanced green and environmentally-friendly sandstone aggregate production line with advanced domestic technology and equipment. After a rigorous inspection of the operation sites of many manufacturers and equipments in the market, the company affirmed the brand strength for FTM, advanced R&D technology, reliable product quality and perfect after-sales service, and finally reached cooperation with FTM.

Project Overview

Material: pebble

Capacity: 800t/h

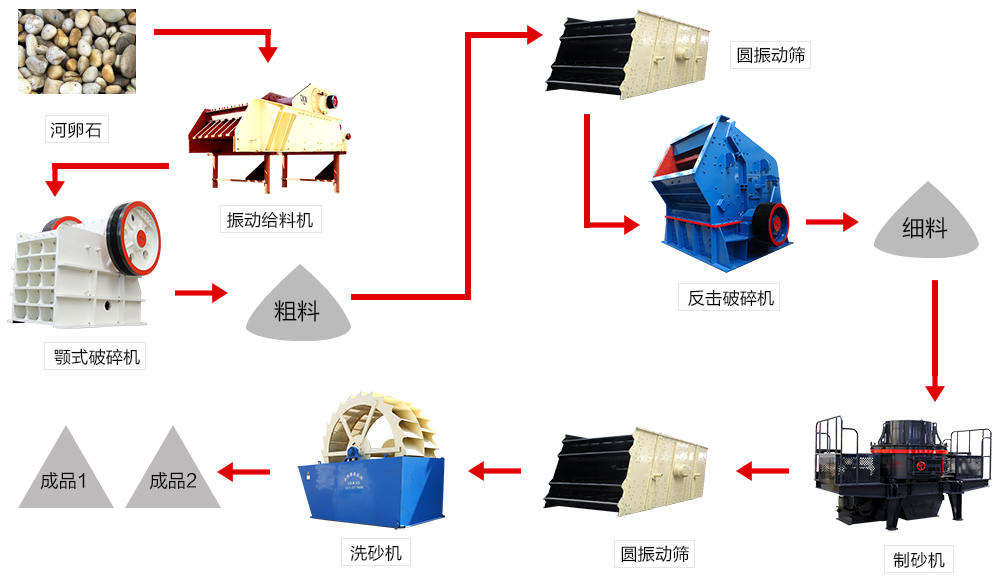

Production line configuration: jaw crusher, impact crusher, cone crusher, sand making machine, etc.

Project Benefits

1. The plan is reasonable and the output is up to standard.

The overall plant uses a combination of jaw crusher, impact crusher and sand making machine, combination of coarse and fine cavities. It can not only meet the production requirements, but also ensure the product size. After the project is put into production, the production scale can reach 10 million tons of machine-made sand every year.

2. The product has excellent particle size and high crushing efficiency.

After professional analysis of the customer's on-site materials, the engineer recommended that the project use a cone crusher to crush the material and then use the sand making machine to make sand. Our cone crusher has been technically improved and uses laminar crushing to not only make the product even better, but also to improve the crushing efficiency. What’s more, the FTM sand making machine has a dual function, which can realize shaping and sand making at the same time, and produce fine aggregate of sand and gravel.

3. Intelligent operating system

The cone crusher is operated by an automated intelligent display screen, which can detect the running status of the equipment in time. At the same time, it adopts full hydraulic control, which can reduce the input of human resources and greatly shorten the maintenance time of the equipment and obtain greater Economic benefits.

4. Good environmental performance, in line with national standards.

The production line is produced by wet method, and the sewage treatment system is equipped in the production process. The pollution problems in the whole production process are within the controllable range, strictly in accordance with national environmental protection standards.

From the initial consultation and inspection to the design of the project, to the later delivery and after-sales service, Henan Fote Heavy Machinery Co., Ltd has built a comprehensive service system to ensure that it provides professional services and technical support to customers.