Brief Introduction

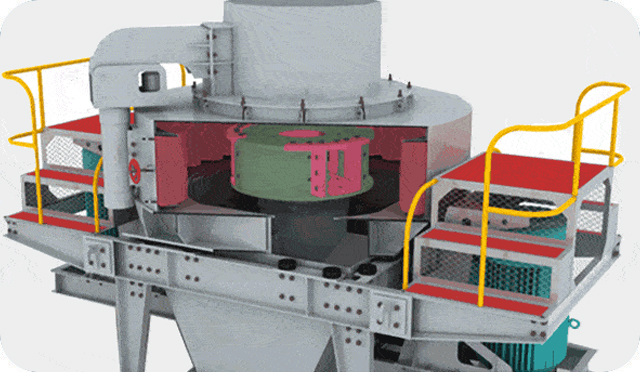

VSI crusher, also known as vertical shaft impact crusher, is advanced equipment specially used for artificial sand making and stone shaping. It adopts the principle and technology of “rock on rock” crushing, which can not only realize the fine crushing of stone materials, but also complete the sand making products. And it has a shaping function, usually with a jaw crusher, a sand washing machine, a vibrating screen, a conveyor and other equipment to form a complete sand production line, which plays an important role in improving the grade of the finished stone.