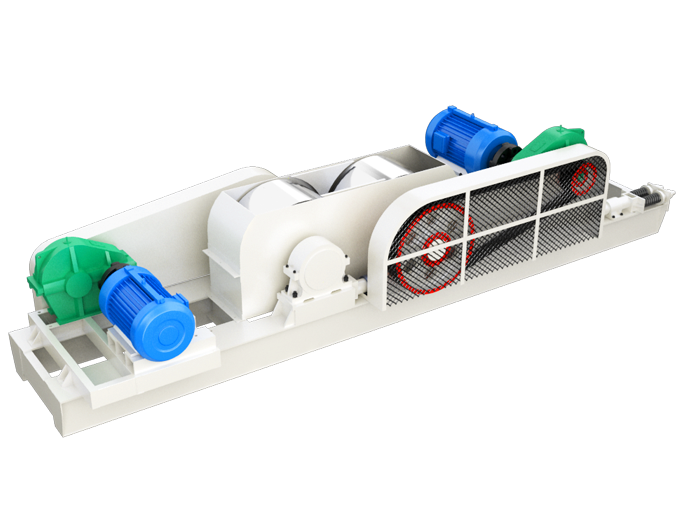

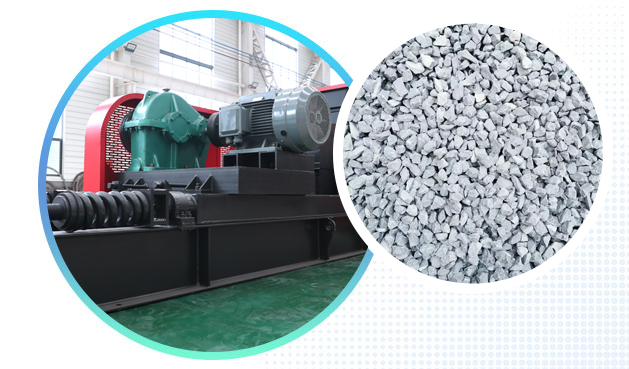

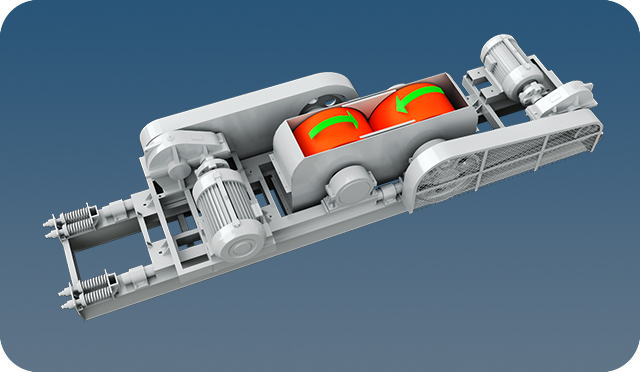

Brief Introduction

The roll rusher is the crushing equipment developed by our company for coarse and fine crushing. It is widely used in metallurgy, building materials, refractory materials and other industrial sectors to crush medium and high hardness materials. What’s more, it has the characteristics of low noise, less dust, reliable performance and convenient maintenance. (The 2PG700×400 roller crusher has good effect on sand making for river pebble.