Multi-cylinder Hydraulic Cone Crusher

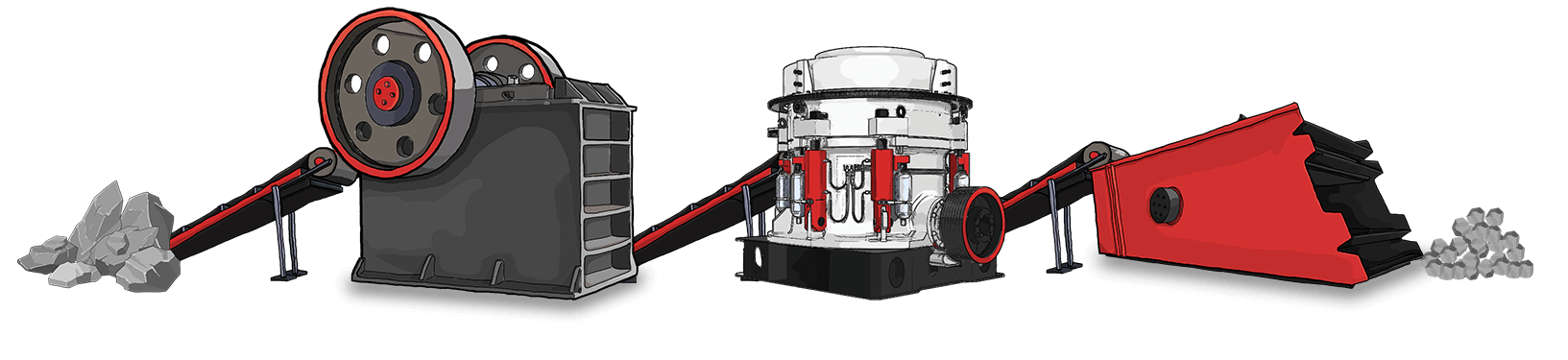

HXHP series multi-cylinder hydraulic cone crusher is a new type of cone crusher developed by our company for crushing high-hard materials and has strict requirements on the shape of the product. The machine is superior to the traditional spring cone crusher. It can be widely used in mining, building materials, transportation, energy, chemical and other industries.

Brief In Multi-cylinder Hydraulic Cone Crusher

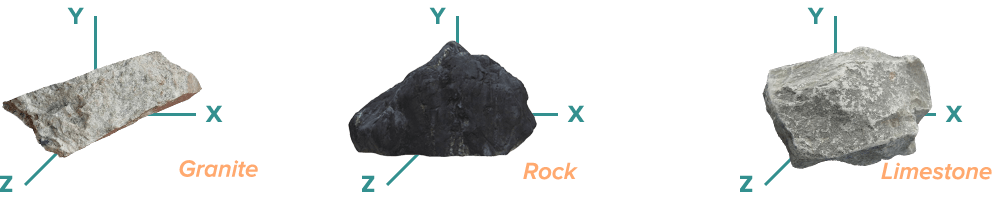

The multi-cylinder hydraulic cone crusher is suitable for crushing various ores and rocks of medium and medium above hardness, such as limestone, iron ore, pebbles, granite, basalt, limestone, etc. Its high speed, high crushing capacity and unique patented design make the finished product have extremely high quality cube shape, and the easy maintenance ensures extraordinary stability operation. It is well-known all over the world and is a new generation of replacement of spring cone crusher and general hydraulic cone crusher in today's mining construction industry.

During operation, the pulley or the coupling is driven by the rotation of the motor, and the transmission shaft and the conical portion make the eccentric shaft rotate periodically under the axial line. After the material enters the crushing chamber from the material inlet, it is crushed by the mutual impact of the eccentric shaft and the rolling wall. The hydraulic safety system can remove the faulty parts from the support sleeve and the fixed taper part by hydraulic pressure when the machine has an iron fault or a boring phenomenon, which greatly reduces the maintenance rate and improves the production efficiency while playing a good insurance function.