Brief Introduction

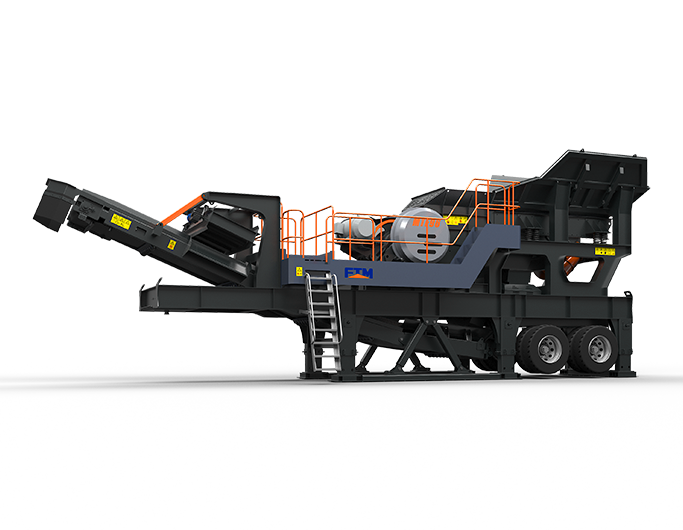

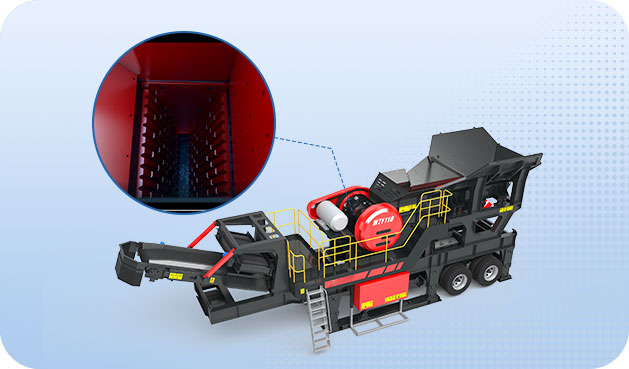

The mobile jaw crusher is mainly composed of a feeder, a jaw crusher, a belt conveyor and a vibrating screen. It adopts an integrated group operation mode, which can be operated separately, eliminating the complex site infrastructure and auxiliary facilities installation of the split components, reducing the labor consumption. The wheeled mobile jaw crushing station is suitable for mine, coal mine, garbage and construction waste recycling, earth and stone works, urban infrastructure, roads or construction sites.