Brief Introduction

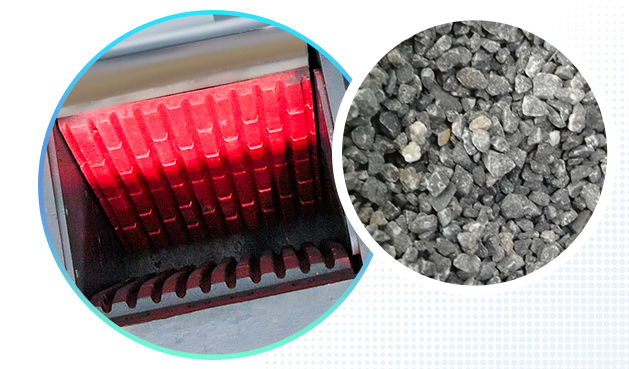

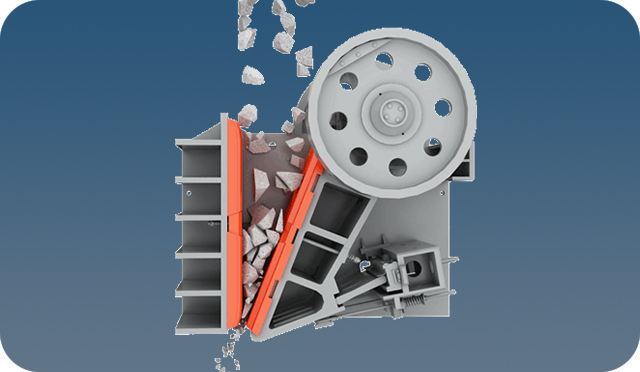

The CJ Series Jaw Crusher is a jaw crusher with excellent performance introduced by Henan Fote Heavy Machinery Co., Ltd. based on the needs of customers. Different from the traditional jaw crusher, its frame is non-welded but detachable, which is convenient for transportation and installation.