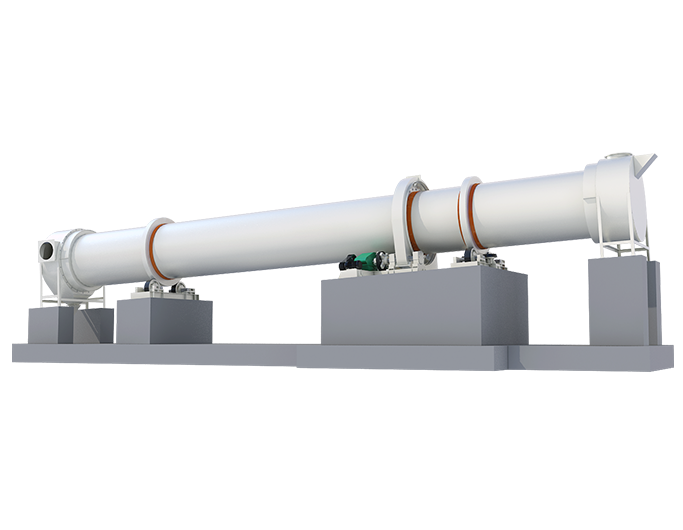

Brief Introduction

Industrial dryer machine in mineral processing. The removal of water from solid materials by thermal drying plays a significant role in modern mineral processing. A great number of dryer types are available.

Extracted ore, whatever the mineral, is usually first crushed and then finally must be dried. Drying is a critical aspect of mineral processing; the ability to control moisture levels from ore to final product helps reduce transportation costs, simplify downstream processing and produce refined products.