Whether in the mining stage or in the processing stage, dry limestone has many benefits and plays

a vital role in the production of high-quality limestone products:

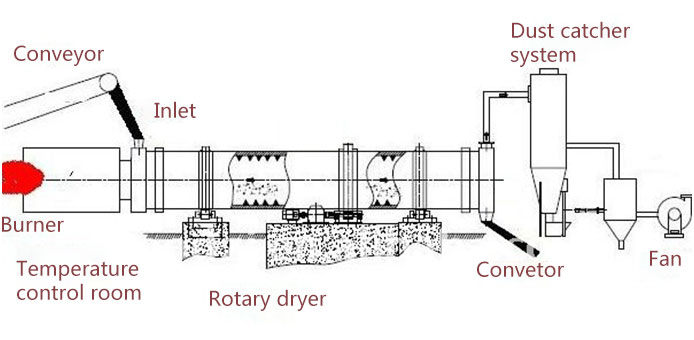

[Limestone beneficiation] Before further processing, the limestone ore is mined,

crushed and stockpiled. If the moisture content of limestone is too high, you need to use a

rotary dryer to dry it.

[Limestone granulation] Limestone granulation requires the binder to adhere the

material to itself in the form of particles. However, the binder will increase the moisture, so

that the limestone processing requires a drying stage. Rotary limestone dryer is a suitable

choice for dry limestone granulation.