NEWS

The Reason That Affects Magnetic Separation Effect

By: Fote MachineryAugust 25th,2020

Magnetic separation is working according to the magnetic difference of mineral particles. In the process of magnetic separation, even if the preparation work is very sufficient, if there is a problem in the magnetic separation stage, the recovery rate will eventually be affected. So what are the factors that affect the magnetic separator?

1. The influence of magnetic separator's own factors

As far as the magnetic separator is concerned, the rotation speed of the cylinder, the deflection angle of the magnetic system, and the gap between the cylinder and the bottom of the groove all affect the magnetic separation effect.

1.1 Rotation speed of magnetic separator cylinder

The rotation speed of the magnetic separator has a greater impact on the processing capacity. The higher the speed of the cylinder, the greater the processing capacity; otherwise, the smaller the processing capacity. Generally speaking, a magnetic separator with a small diameter will use a high speed; a magnetic separator with a large diameter will use a low speed.

The cylinder speed of the magnetic separator will also have a certain impact on the quality of the concentrate. The magnetic separator with high barrel speed only has a great effect on the separation of high-magnetic ore, so it will affect the quality of the concentrate; the magnetic separator with low barrel speed , the speed is relatively slow, the magnetic induction will also select the minerals with weak magnetic properties, which will also affect the quality of the concentrate.

1.2 The deflection angle of the magnetic system

Too large or too small a declination angle of the magnetic system will affect the efficiency of magnetic separation. If the deflection angle is too small, which will affect the quality of the concentrate, so that mineral particles with a small magnetic system have a chance to be selected; If the deflection angle is too large, only the minerals with high magnetism are selected, and there is almost no chance to sort the minerals with low magnetism. Therefore, the quality of the concentrate will be improved, but the tailings grade will be increased, thereby reducing the recovery rate.

Generally, the commonly used magnetic system declination angle is 15°~20°. The specific declination angle needs to be determined according to the operation requirements. After adjustment, if the operating conditions and requirements do not change during production, do not change it.

1.3 The gap between the cylinder and the bottom of the magnetic separator

The size of the gap between the cylinder and the tank of the magnetic separator is one of the factors that affect the efficiency of the magnetic separator. If the gap is too small, the slurry will not pass smoothly and affect the throughput. If the gap is too small, the slurry will not pass smoothly, which will affect the processing capacity. At the same time, the strong magnetic and weak magnetic minerals will be separated together due to the large magnetic field strength, thereby reducing the quality of the concentrate. If the gap is too large, the separation force for minerals with weak magnetic system will be reduced. Although the quality of the concentrate is improved, the recovery rate is reduced.

Generally, the gap is within the range of 35-60mm, and the specific gap size needs to be determined according to the actual situation.

2. The influence of the slurry concentration of the magnetic separator

The concentration of the magnetic separator slurry refers to the overflow concentration of the classifier. If the slurry concentration is too large, it will cause the separation concentration to be too high, and the concentrate particles are easily covered or wrapped by the finer gangue minerals. This will seriously affect the quality of the concentrate. If the slurry concentration is too small, not only the separation concentration is too low, but also the flow rate will be increased, the separation time will be shortened, and some fine magnetic particles that have the opportunity to be separated will fall into the tailings, thus reducing the recovery rate.

Generally, the slurry concentration of the magnetic separator should not exceed 35%, and it is recommended to control it at about 30%. The slurry concentration adjustment needs to be determined according to specific conditions.

3. The influence of the particle size of ore

The particle size of the ore fed by the magnetic separator is an important factor that affects the magnetic separation effect of the magnetic separator. If the particle size of the ore fed is small, it means that the monomer dissociation is high and better separation indicators can be obtained. If the particle size of the ore is large or coarse, it means that the mineral monomer is not sufficiently dissociated, and a part of the gangue is still combined with the magnetic particles, thereby reducing the grade of the concentrate.

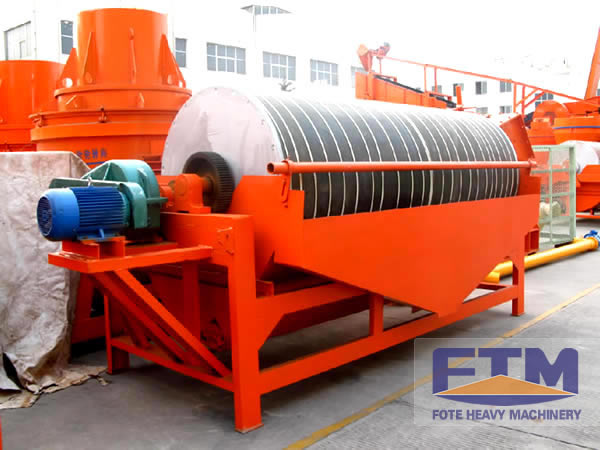

FTM®Magnetic Separator have passed the authentication of ISO 9001, CE and GOST. Fote Brand is a Chinese Famous Brand. Reliable quality and high performance is our products’ key, our products are well known at home and abroad and now we have thousands of users throughout more than 160 countries in the world. Welcome to consult with.