NEWS

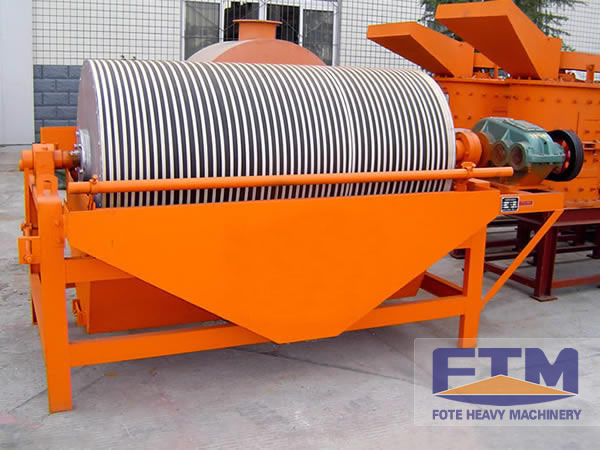

Magnetic Separator from FTM

By: Fote MachineryJuly 24th,2019

The magnetic separator is divided into the ordinary magnetic separator and high-strength magnetic separator. It is suitable for wet magnetic separation of hematite, pyrrhotite, roasting ore, and other materials with a particle size of 3mm or less. It is also used for iron removal operations for materials such as coal, non-ferrous materials, metal ore, and building materials. According to the needs of users, FTM can provide magnetic separation of much different surface strength such as down-flow, semi-reverse, and counter flow. This series of magnetic separation equipment has the advantages of simple structure, large processing capacity, convenient operation, and easy maintenance. It is one of the important iron ore processing equipment and can be used as hematite ore dressing equipment and hematite beneficiation process.

Magnetic separators mainly use the magnetic difference between minerals. It is precise because of such differences that minerals can be selected according to the relationship between magnetic strength. The slurry processed by the wet magnetic separator flows from the mine tank to the groove for receiving the slurry, and then gradually flows out into the feeding area under the scouring of the water spray pipe.

During the processing, the non-magnetic minerals in these minerals will fall off during this continuous turning process, and those that are adsorbed on the surface of the cylinder of the magnetic separator are the concentrates left by the equipment while producing. In the case of the magnetic action of the cylinder of the magnetic separator, these concentrates basically reach the weakest ends of the magnetic force with the rotation of the cylinder, and under the action of the water flow discharged by the unloading water, then enter the concentrate tank of the concentrate. Other minerals that have been left behind after treatment are discharged to the outside of the cylinder. Such minerals that are of little use are tailings.

It is in this complicated process that some phenomena such as magnetic clusters or flux linkages appear. During the processing, many minerals are adsorbed on the magnetic cylinder due to the action of the magnetic poles. Since the magnetic poles on the cylinder are mainly arranged alternately in the direction of rotation of the cylinder, they are not very fixed during the production process, and it is for this reason that the magnetic stirring phenomenon occurs.

In the process of processing minerals, the magnetic separator equipment can separate the concentrate and tailings. From the above analysis, it seems that there are two main factors determining the processing capacity of the magnetic separator: the magnetic field of the equipment and the power of magnetic separator equipment. Henan Fote Heavy Machinery Co., Ltd. is a large magnetic separator manufacturer. In addition, we also produce related mining equipment such as powder making machines and building materials equipment. Consult online or come to visit our factory to get more details.

Email: sales@sinoftm.com

Address: Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China