NEWS

Introduction and Daily Maintenance of Flotation Machine

By: Fote MachineryDecember 10th,2020

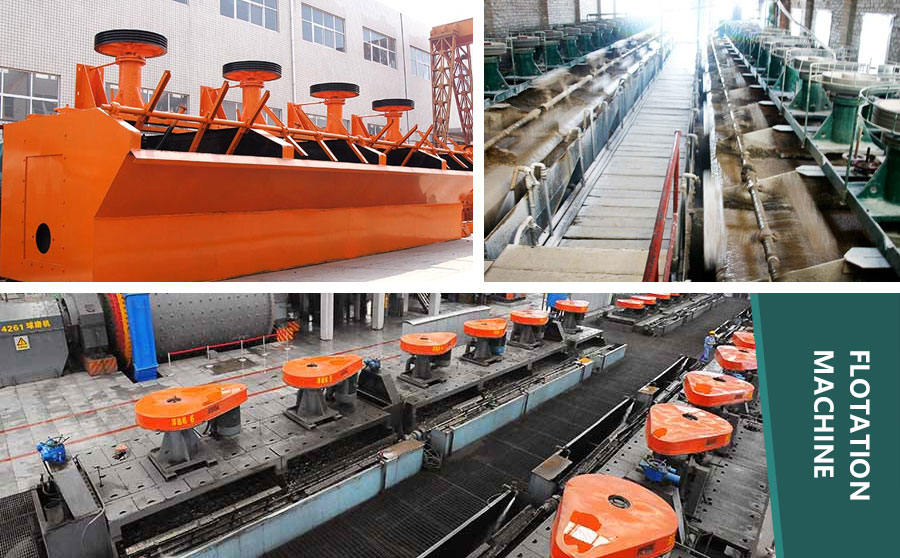

Brief In Flotation Machine

Flotation machine refers to the mechanical equipment that completes the flotation process. The flotation machine is used to separate non-ferrous metals, ferrous metals, rare metals, and non-metallic minerals such as copper, lead, zinc, nickel, and molybdenum, after rough selection, sweeping, selection and reverse flotation operations, for useful minerals.

We designed flotation machine has SF flotation machine, BF flotation machine, XCF flotation machine, and KYF flotation machine. Different types of flotation machines have different characteristics, and customers can choose according to actual needs.

Classification

1.SF flotation machine:

Self-priming slurry without foam pump.

Conducive to the flotation of coarse-grained minerals.

The dead angle of the forward inclined water tank is small, and the foam moves quickly in it.

2.BF flotation machine:

Low operating cost, strong durability of wearing parts.

It can handle a wide range of particle size and high sorting accuracy.

3.XCF / KYF flotation machine:

Strong mixing capacity, simple structure.

The air is evenly dispersed, the air-slurry mixture is good, and the tailings deposit is less.

Working Principle

In the flotation machine, the slurry treated with the agent is stirred and aerated to selectively fix some of the mineral particles on the bubbles; it floats to the surface of the slurry and is scraped out to form a foam product, and the rest remains in the slurry In order to achieve the purpose of separating minerals.

The flotation machine is driven by the V-belt drive of the motor to rotate the impeller, which produces a centrifugal effect to form negative pressure. On the one hand, it sucks in sufficient air to mix with the pulp. On the other hand, the mineral slurry is mixed with the medicine and the foam is refined at the same time, so that the mineralized foam is formed on the mineral binding foam. By adjusting the height of the gate, the liquid level is controlled so that the useful foam is scraped out by the scraper.

Structure

The flotation machine is mainly composed of flotation cell, mixing device, aeration device, mineralized foam discharge device, electric motor, etc.

Flotation cell: It has a slurry inlet and a gate device for adjusting the slurry surface. It is mainly composed of a storage tank welded by steel plate and a gate welded by steel plate and round steel.

Mixing device: It mainly composed of pulleys, impellers, vertical shafts, etc., used to mix the ore slurry to prevent the ore from settling in the tank.

Aeration device: It consists of an air inlet pipe. When the impeller rotates, negative pressure is generated in the impeller cavity, so air is sucked in through the hollow pump tube and dispersed in the slurry, forming air bubbles.

Mineralized foam discharge device: This device is mainly composed of a motor, a reducer and a scraper to scrape the foam floating on the cell surface.

Advantages

1. Strong stirring power can ensure the suspension of mineral particles with larger density and particle size, and can promote the dispersion of insoluble agents.

2. Large aeration volume, easy adjustment, stable liquid level, and good sorting index, which are beneficial to increase output and adjust process.

3. The circumferential speed of the impeller is low, the life of the impeller cover plate is long, and the slurry is circulated up and down in a fixed manner, which is beneficial to the suspension of coarse minerals.

4. Small footprint, simple operation and control, and convenient adjustment.

Daily inspection items:

1. Whether the bolts of each part are loose, whether the triangle belt is complete, and whether the safety cover is complete and firm;

2. Whether the temperature of the motor and spindle bearing is normal;

3. Whether the inspiratory volume is normal;

4. Whether the lubrication points are kept lubricated and whether the lubricating oil is sufficient;

5. Whether the discharge valve and the box body are kept straight;

6. Whether the tank is leaking;

7. Whether the scraper parts are in good condition.

For the flotation plant, on the one hand, it is recommended to find equipment manufacturers with the overall qualification of the plant to purchase the flotation machine. On the other hand, it is recommended that the operators and maintenance personnel of the flotation machine improve their own operating skills and respond to the occurrence of the flotation machine in time. Various conditions ensure the smooth progress of the entire flotation operation and avoid unnecessary economic losses.