Gold Mining Equipment

Raw material: gold ore

Related Products: jaw crusher, ball mill, classifier, flotation cell, mixing barrel, concentrator, dryer and so on

Technological Advantages: high efficient, low energy consumption, strong handling capacity, economical and reasonable.

Are you interested in our machines? Get Quotation

Welcome to Visit Factory

Introduction of Gold Mining Equipment

Features and prospects

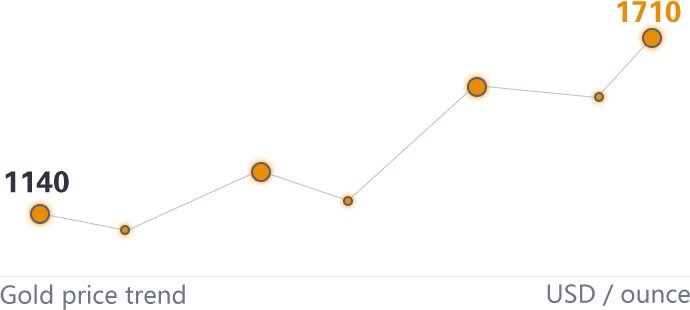

Gold is the noblest of metals. The gold prices have tripled in the last 10 years and the long-term price trends still point up, so there's never been a better time to find your own! And the best way is that you can find and recover placer gold in numerous ways— with a variety of products and information on this website that will meet your needs.

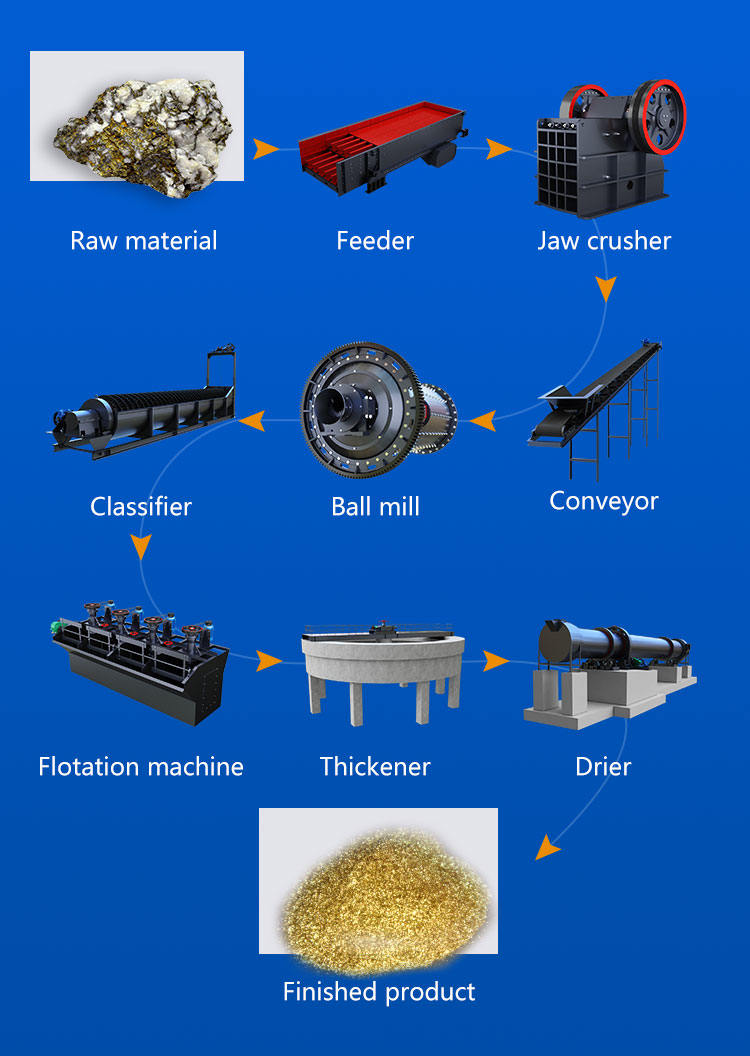

Detailed Description of Gold Ore Mining

Gold mining equipment is mainly used for separating gold ore in ore dressing industry. The methods for processing gold ore include Flotation separation process, Magnetic separation process, Gravity separation process. The flotation separation process is one of the most important way to process gold ore.

1. The Main Equipment

Components of the flotation separation process are mainly composed of jaw crusher, ball mill, classifier, flotation machine, thickener, drier, feeder, and conveyor, etc.

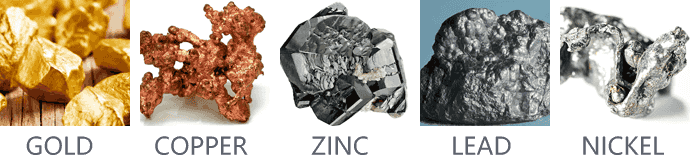

2. The Handling Materials

The flotation separation process is mainly applied to separate gold copper, zinc, lead, nickel, and other non-ferrous metals, and to make rough or fine separation of ferrous metal and non-metals..

3. Influencing Factors

Many factors affect the flotation process: granularity (MOG), pulp density, medicament addition and adjustment, bubble and foam adjustment, pulp temperature, flotation process, and water quality.

200tph Complete Set Gold Mining Equipment in Nigeria Project

Capacity: 200tph

Applied Material: Gold Ore

The Main Configuration:jaw crusher, cone crusher, ball mill, spiral classifier, flotation machine.

Working Principle:Flotation cells run by the triangle belt of the electrical motor driving the impellor to rotate, producing a centrifugal effect that will form the negative pressure.

The flotation separation process of flotation concentrator: first, feed the pulp into the flotation plant, add medicament fully stir. When mixing, use air to make the particles attaching themselves to air bubbles. Bubble floating on the surface is scraped out, so as to achieve the objective of separating particles and impurities.

Customer Evaluation

I have always wanted to participate in the mining business, and the revenue from the mining business is relatively stable. However, as a technical novice, it is not easy to participate in the mining business. Later, I came into contact with Fote and found that mining the right mining pool has become so simple. Fote's one-stop service not only allows you to get mining equipment at a preferential price, but also reassuringly stable and complete services. thank fote for my mining income.

Why Buy Fote Mining Equipment?

Safe and stable, high yield

Large-scale mines around the world, with stable power supply and favorable price, ensure that the mining machine operates online 7x24

Purchase Process

1. Contact online/leave a message/send an email to tell your needs

2. Tailor the production plan for you

3. Come to the factory for inspection and test

4. Strict inspection and ship on-time and delivery

5. Installation accompanied by a professional team

6. Regular return visits after-sales for life