Why Choose Briquette Plant?

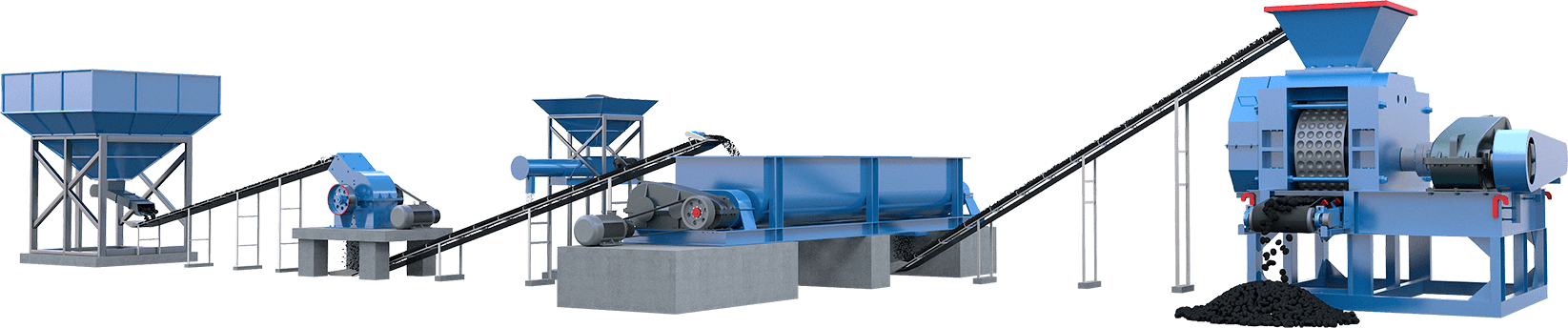

Based on years of experience, customers often require a complete briquette production line when selecting briquette equipment. This includes the entire process from raw materials to the final product, which not only saves time and effort but also increases efficiency. With the processing of raw materials, costs can be greatly reduced and the output of briquette can be increased, resulting in higher profitability. Furthermore, when customers purchase a complete briquette production line, our factory can provide more favorable discounts, resulting in a win-win situation for both parties.

Application: Coal powder molding; Dry powder molding; Flue gas desulfurization gypsum molding; Coke powder molding; Iron filings and various metal ore powder molding.