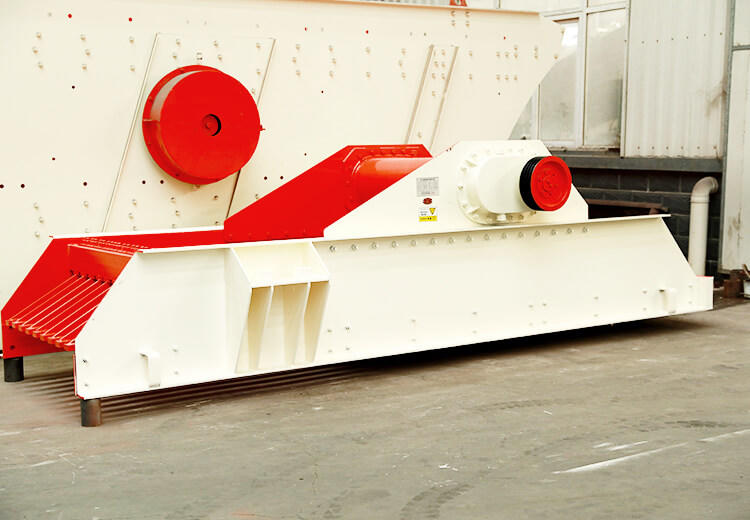

Vibrating Feeder

The vibrating feeder is also called the vibrating feeding machine. In the production process, the vibrating feeder can feed the block and granular materials uniformly, regularly and continuously from the storage bin to the receiving device. It can continuously and evenly screen out and feed for the crushing equipment in sand stone production line.

Brief In Vibrating Feeder

The feeding machine produced by our company (Henan Fote Heavy Machinery Co., Ltd.) is a linear vibrating feeder with the characteristics of stable vibration, reliable work and long service lifespan. It can continuously and evenly feed and screen out the materials for the crushing devices. It is widely used in crushing and screening combined equipment in mineral processing, building materials, silicate and chemical industries. It is an indispensable and energy-saving new device for crushing and screening production lines.

The vibrating feeder can adjust the vibrating force during operation, and can change and control the flow at any time. It has the characteristics of simple structure, reliable operation, convenient adjustment and installation, light weight, small size and convenient maintenance. When using a closed structure body, it can prevent dust pollution.