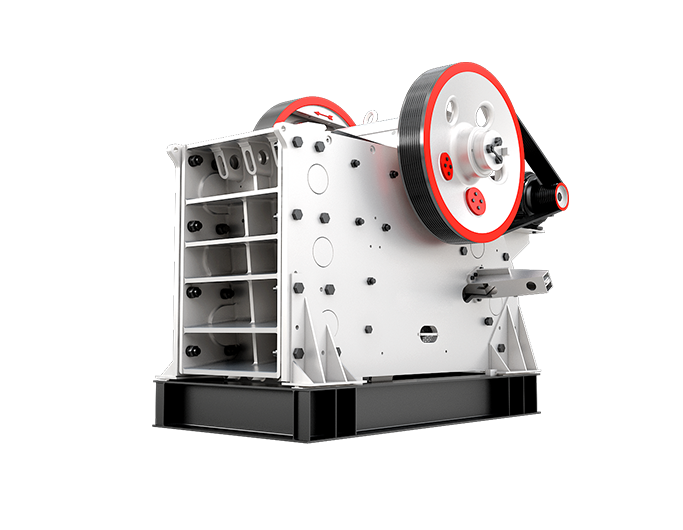

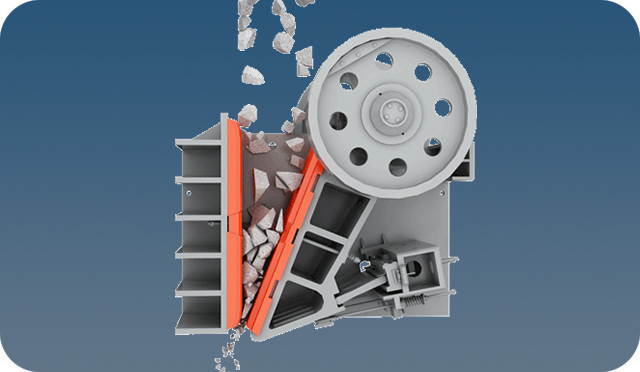

Brief Introduction

Granite crusher is professionally designed for primary fine crushing of kinds of granite stones. We have types of granite crusher for sale, customized solution for you, meeting different needs.It is widely used for primary secondary fine crushing of granite, granite quarry, blue stone, boulder, hard core, hard rock, etc. Adjustable final size meeting different needs. Following is common final output size.