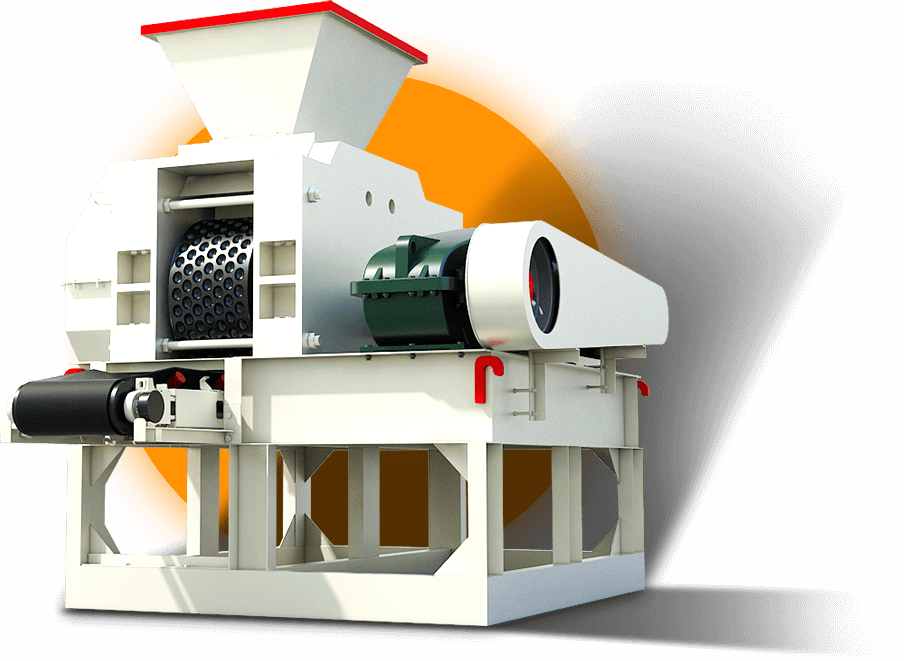

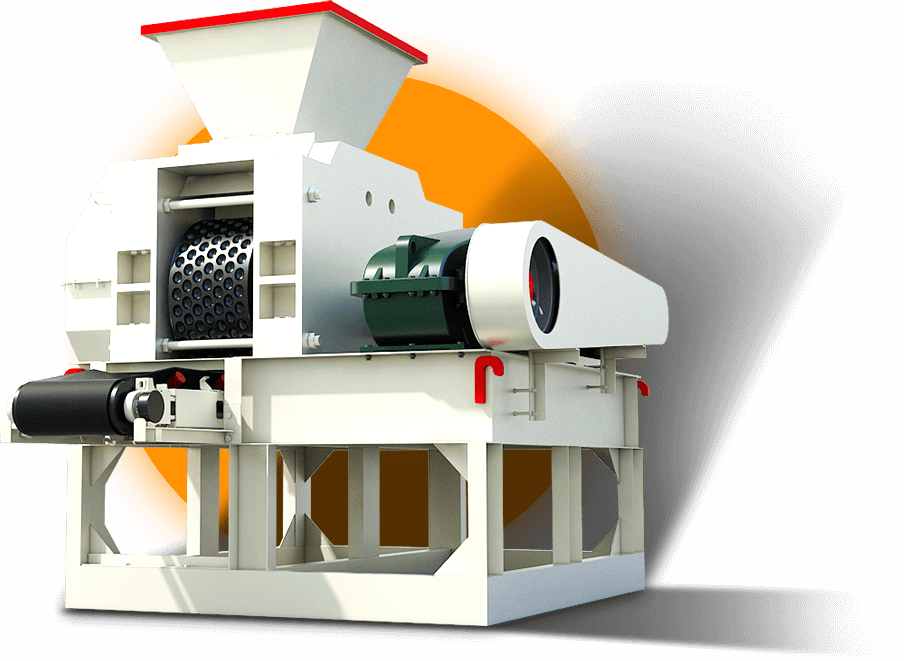

Coal Briquette Machine

Processing Capacity1-5T/H (Hot Sale), 5-10T/H, 10-35T/H

Applicable materialsCoal powder, brown coal, coal slime, coal ash, coal slurry, coal slag, coke, etc

Contact Us for Video Tour of the Factory

E-mail:sales@sinoftm.com

Processing Capacity1-5T/H (Hot Sale), 5-10T/H, 10-35T/H

Applicable materialsCoal powder, brown coal, coal slime, coal ash, coal slurry, coal slag, coke, etc

Contact Us for Video Tour of the Factory

E-mail:sales@sinoftm.com

The coal briquette machine is mainly used to compress powdery materials that are difficult to form. It is characterized by high forming pressure, adjustable host speed, and screw feeding device. This machine is widely used in refractory materials, power plants, metallurgy, chemical industry, energy, transportation, heating, industry, agriculture, barbecue and other fields. This machine is suitable for single machine operation and large-scale production line.

Round

Round

Square

Square

Pillow

Pillow

Oval

Oval

In addition, customers can customize the shapes if they have special needs.

Firstly, the material is fed into the ball mold on the press roller.

With the rotation of the pressure roller, the pressure of the material is small or large. Under the action of the huge line pressure, the material becomes the finished ball from the powder.

After the material passes the line, the molding pressure is rapidly reduced, so that the material enters the off-ball state, and the ball is smoothly removed.

Now FTM®Coal briquette machine has been widely used in large and medium-sized enterprises all over the world. It saves a lot of resource consumption and economic cost for the enterprise.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

We guarantee that our products are all up to standards set for mining machinery.

We will deliver products timely by contract.

We will supply you with installation drawings, specifications and operation manual.

We offer lifetime warranty and components for products.

Henan Fote Heavy Machinery Co., Ltd., has been in existence for more than 40 years since its establishment. It has four production bases in China and its products are sold to more than 160 countries around the world.

ISO 9001, CE and GOST——Reliable Machine Quality

40+ Production Experience——Perfect Service and Technical Support

Exported to 160+ Countries——Trustworthy Mine Brand

100% Factory Price——Low Investment Cost

Contact online/leave a message/send an email to tell your needs

Tailor the production plan for you

Come to the factory for inspection and test

Strict inspection and ship on-time and delivery

Installation accompanied by a professional team

Please write down your requirements in the form below. We will reply to you within 24 hours.

Office AddNo. 8, Tanxiang Road, Zhengzhou High-tech Industrial Development Zone

E-mail sales@sinoftm.com