Brief Introduction

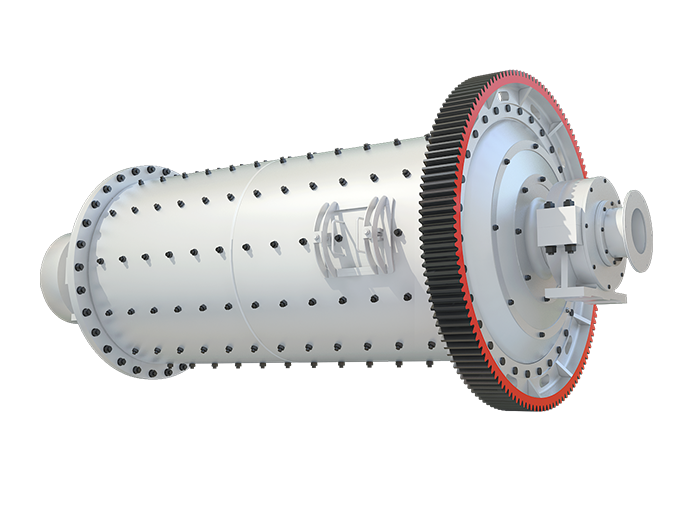

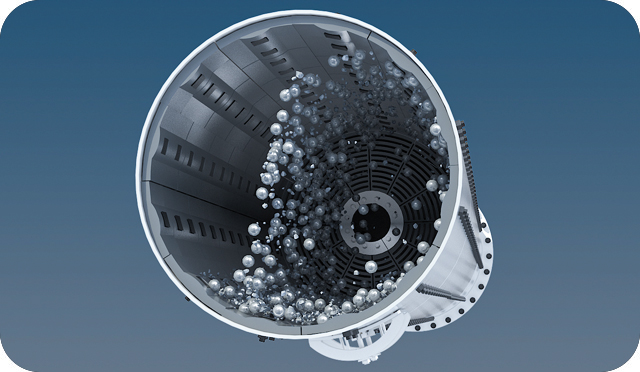

The ceramic ball mill is a ball mill with a ceramic substrate. It is a new type of energy-saving ball mill that can be used for grinding various materials, both dry and wet. The machine can be used according to different product types to meet different needs. Ceramic ball mill is suitable for the mixing and grinding of various materials, such as river quartz, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, copper ore, river sand, and glass in many industries such as silicate products, building materials, metallurgy, chemical materials, fertilizers, and non-ferrous metal dressing and glass ceramics.