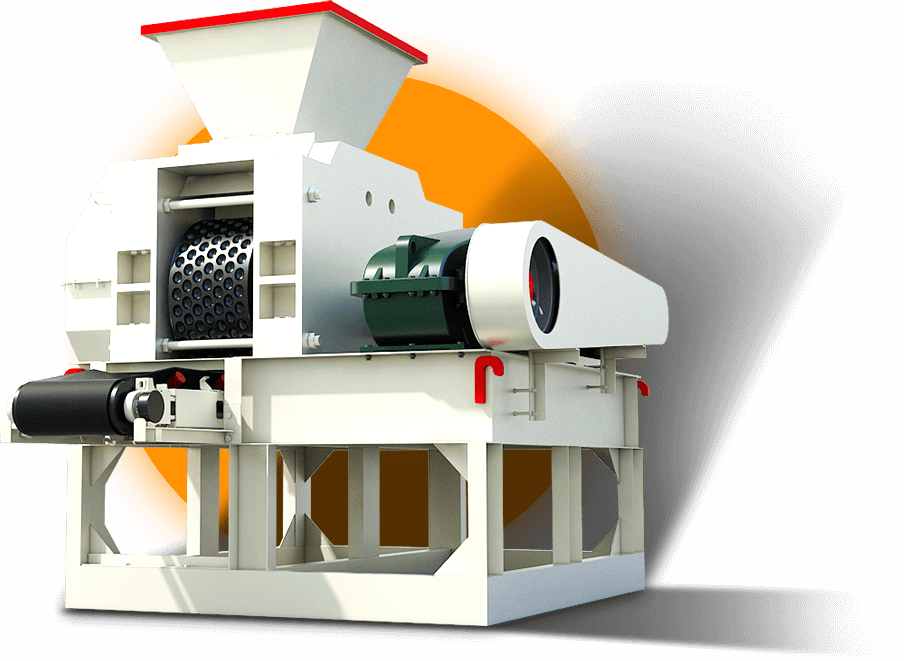

Briquette Making Machine

Processing Capacity1-5T/H (Hot Sale), 5-10T/H, 10-35T/H

Applicable MaterialsCharcoal, Charcoal Powder, Coal, Carbonized Materials (from coconut waste, rice husk, wood chips, etc.)

Contact Us for Video Tour of the Factory

E-mail:sales@sinoftm.com