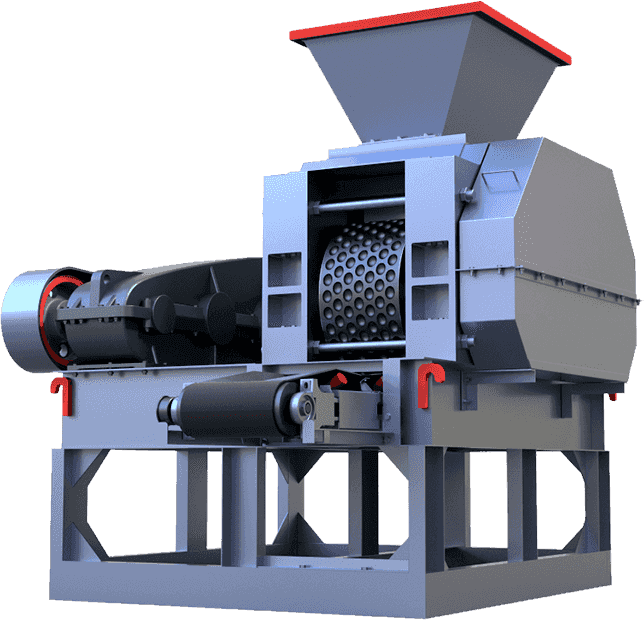

Briquette Machine

Processing Capacity:1-35t/h

Applicable materials:coal, charcoal, slag, gypsum, sludge, coking coal, iron powder, steel slag and other metallic materials

Processing Capacity:1-35t/h

Applicable materials:coal, charcoal, slag, gypsum, sludge, coking coal, iron powder, steel slag and other metallic materials

The briquetting machine is a device that presses powdered materials into balls which are easy to transport, burn and smelt. Materials frequently handled by the company include coal, peat, charcoal, concentrate tailings, etc.

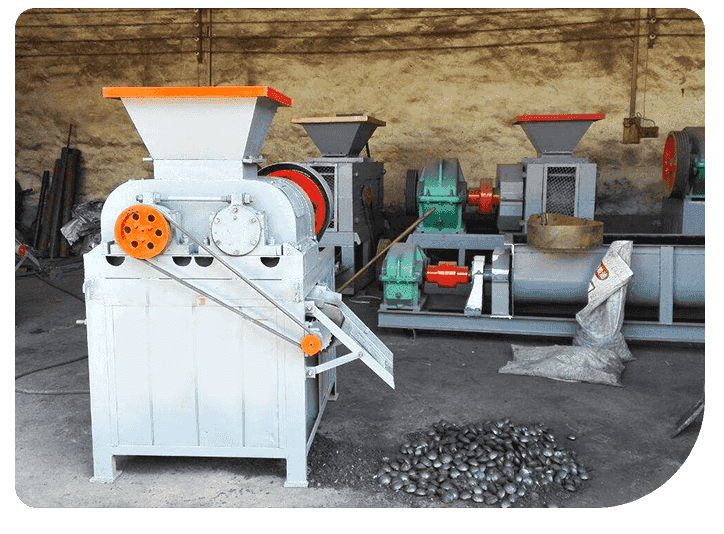

Common shapes: round, square,pillow, oval.

(In addition, customers can customize the shapes if they have special needs, such as rectangle, heart

shape and so on.)

1. Firstly, the material is fed into the ball mold on the press roller.

2. With the rotation of the pressure roller, the pressure of the material is small and large. Under the action of the huge line pressure, the material becomes the finished ball from the powder.

3. After the material passes the line, the molding pressure is rapidly reduced, so that the material enters the off-ball state, and the ball is smoothly removed.

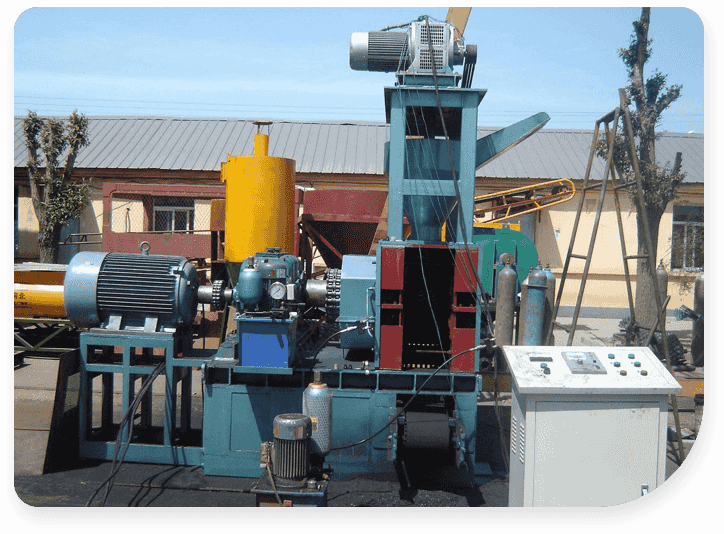

Now the briquette machine has been widely used in large and medium-sized enterprises all over the world, which has good economic and social benefits.

1.High density of molded spheres

2. Easy to transport and smelt

3. Increased waste utilization

4. Energy consumption and environmental protection

1. Industrial powder: Coal, charcoal, slag, gypsum, sludge, iron powder, coking coal.

2. Mining materials: Widely used in mine tailings treatment to suppress powdery materials that are difficult to form.

3. Metallurgical industry: Dust ash, pool mud, steel slag, iron powder, aluminum ash powder, manganese ore powder, etc.

| Model |

Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

PRODUCT

PRODUCT

With a friendly technical discussion with your engineers, we are very satisfied with your production and the company's reputation in the industry for many years let us make sure that we have found the most suitable supplier.

PRODUCT

PRODUCT

Customer's Feedback:Fote's excellent customer service has earned more trust. The production flow is smooth and there are no failures. The wear-resistance ability is strong and working efficiency is high. We are very satisfied with the briquette machine performance.

Henan Fote Heavy Machinery Co., Ltd., has been in existence for more than 40 years since its establishment. It has four production bases in China and its products are sold to more than 160 countries around the world, including South Africa, Tanzania, Nigeria, Ethiopia, Zambia, Nigeria, Uganda, Ghana, India, Indonesia, Egypt, Australia, Vietnam, Bangladesh, etc.

We are waiting for you in all directions

Chat Online

Office Add:

No. 8, Tanxiang Road, Zhengzhou High-tech Industrial Development ZoneE-mail:

sales@sinoftm.com