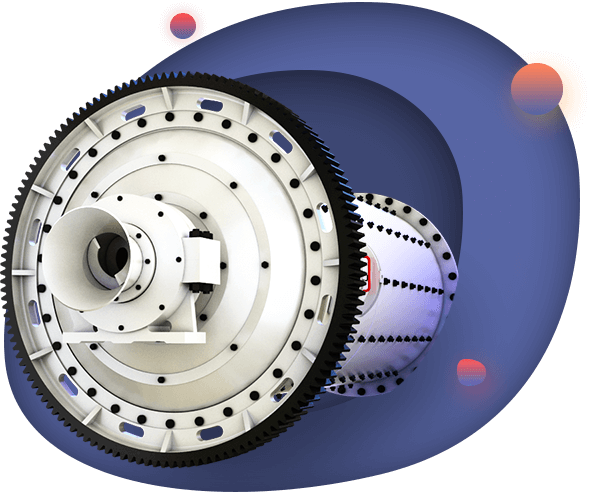

Ball mills is a key equipment for grinding materials sell@chinaftm.com

Production capacity

Feeding size

Material handling effect

gold ore

copper ore

limestone

manganese

chrome

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings, and glass ceramics. Dry or wet grinding of various ores and other materials.

Energy-saving: fully hydraulic operation, easy to use and automate.

Energy-saving: fully hydraulic operation, easy to use and automate. High grinding efficiency:High quality of the lining and grinding body .

High grinding efficiency:High quality of the lining and grinding body . Good operating conditions:stable operation, less dust.

Good operating conditions:stable operation, less dust.

![]() Ball mill working principle

Ball mill working principle

FTM company's advanced technology of ball mill machine allows optimizing production according to demand, which brings us doubles production.

The ball mill process is situated in northern Mexico, where there is the copper on a large scale. Our specialists and engineers design a 3t/h ball mill process for customers.

Capacity: 3t/h

Material: Copper ore

Location: Northern Mexico

We have co-operated with the FTM company for five years. The ball mill is used for iron ore milling, which is convenient to use and easy to maintain, the machine has high processing precision.

The company aimed to increase recovery, and reduce power consumption. Choosing a more reliable and efficient machine would enable the entire process to be more efficient.

Capacity: 22t/h

Material: Iron ore

Location: Balochistan, Pakistan

FTM company's advanced technology of ball mill machine allows optimizing production according to demand, which brings us doubles production.

The gold belt in the southern shore of Lake Victoria is a large gold mining area in Tanzania. Now it has been working for a long time.

Capacity: 60t/h

Material: Gold ore

Location: South Lake Victoria, Tanzania

Professional mining machinery manufacturer with over 40 years of experience.

Ⅰ

Ⅰ

24/7 online service

Ⅱ

Ⅱ

Customize the solution for free

Ⅲ

Ⅲ

On-site service and training

Ⅳ

Ⅳ

Round-the-clock tech support

The favorable price to provide you with quality services

As the advanced manufacturer and exporter in china, our ball mills are factory-direct sold, which offer you premium quality and better service.

Company strength

Company strength

Brand:FTM

Set up:1982

Current Headcount:2,300+

Covering area:350,000m²

Factory area:260,000m²

Product types

Product types

Crushing equipment

Beneficiation equipment

Building materials equipment

Grinding milling equipment

Business types

Business types

Manufacturer

Importer

Exporter

Staple market

Staple market

Southeast Asia

Africa

Middle East

South America

East Europe

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Reference motor (kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

| Model |

Shell Specifications (mm)

|

Shell rotation speed (r/min) |

Feeding size (mm) |

Discharging size (mm) |

Processing capacity (t/h) |

Power (kw) |

Total weight (t) |

|

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 |

5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

You can leave a message online or send us an email

Provide customized solution according to your specific needs.We are responsible for each customer and dedicated to realize win-win.

We will strictly protect the privacy of users'personal information and never disclose it.

Copyright: China Henan Fote Mining Machinery Co., Ltd.All rights reserved