Cement Grinding Station Introduction

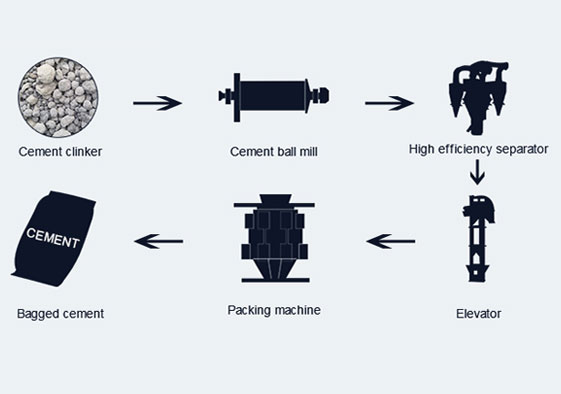

Cement grinding station is a stage in the cement production line, which is to add a proper amount of mixed material to cement clinker, then grind it to produce finished cement. Mixed mterials generally include gypsum, fly ash, slag powder, etc.

Cement Grinding Station Applied Materials: Limestone, Clinker, Gypsum and lending Materials.

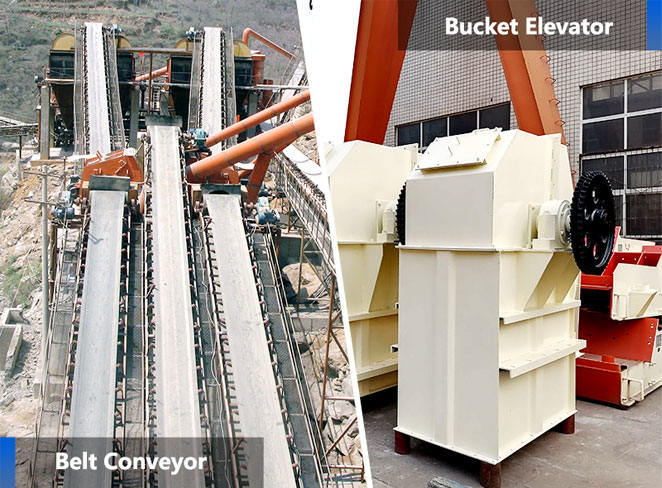

Cement Clinker Grinding Station Plant Includes:

- Limestone, Gypsum and Blending Materials Crushing System

- Cement Proportioning and Grinding System

- Cement Storage and Bulk Loading

- Cement Packing and the Finished-product Storage