NEWS

Wet Ball Mill Vs Dry Ball Mill

By: Fote MachineryOctober 23rd,2020

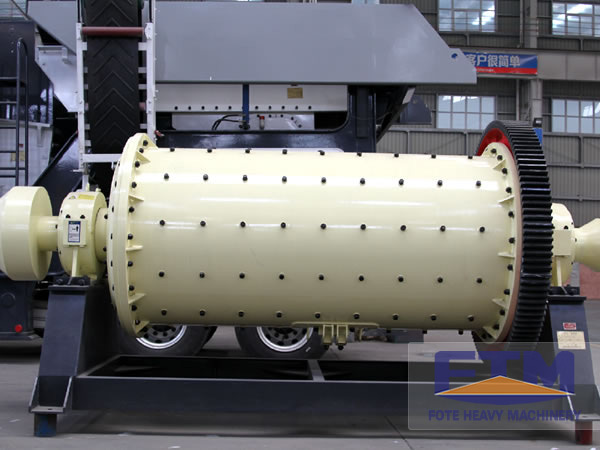

Ball mill is a common equipment in grinding equipment, and it is also the key equipment for grinding materials after crushing and screening. According to the classification of grinding methods, the ball mill can be divided into dry ball mill and wet ball mill. So, what is the difference between dry ball mill and wet ball mill?

The differences between wet ball mill and dry ball mill are mainly reflected in three aspects: first, the working principle is different; second, the structure is different; third, the scope of application is different.

1、The Difference of Working Principles

Dry Ball Mill: When it is running, the materials enter the first chamber of the mill evenly through the feeding device. The chamber is equipped with lining plates and steel balls of different specifications. The centrifugal force produced by the rotation of the ball mill barrel brings the steel ball to a certain height and then falls down, thus crushing and grinding the material. After coarse grinding in the first chamber, the material enters the second chamber through a single-layer partition board. The chamber is equipped with a flat lining board and equipped with steel balls of different specifications to further grind the material. Finally, the qualified materials are discharged through the discharge grate.

Wet Ball Mill: It is similar to that of dry ball mill, but there are some differences. The wet ball mill needs to add some water or anhydrous ethanol in the grinding process, which means there are certain requirements for grinding concentration. The amount of water is determined by the nature of the material. The qualified materials are discharged out of the barrel, and the unqualified materials are returned to the wet ball mill for regrinding.

2、The difference of The structure

Both the dry ball mill and the wet ball mill include the main parts such as the feeding part, the discharging part, the rotating part and the transmission part.

The structure of the dry ball mill is more complex than that of the wet ball mill, and its discharge port is in the shape of a straight cylinder. At the same time, it is equipped with an induced draft device, a dust discharge pipe and a dust remover, which is also determined by its working principle.

The structure of the wet ball mill is simple, without adding too many auxiliary accessories. The discharge port is in the shape of a trumpet, with a built-in screw device to facilitate discharge.

3、 The Difference of Application Scope

Generally, the dry ball mill is suitable for all kinds of metal ores and non-metal ores, including materials that will react when encountering water, such as cement, marble, or products that are required to be stored and sold in the form of powder.

Wet ball mill has a wide range of applications, which can handle various metal and non-metal ores, including gold, silver, copper, iron, molybdenum, phosphate, feldspar, fluorite and so on. The ore that needs to be separated is usually treated by wet ball mill.

These are the three major differences between dry ball mill and wet ball mill, and how to choose them. Only by finding out the grinding method suitable for the material, can the ball mill operate with high quality and efficiency. Each of the two grinding equipment has its own advantages. We still make rational choice after considering the material property, characteristics, product requirements, working environment and other aspects. If you have any other questions, welcome to consult with.