NEWS

The importance of pressure rollers for briquette machine

By: Fote MachineryMarch 31st,2020

The pressure roller is the core part of the briquette machine. Two huge pressure rollers move in the opposite direction at the same speed and press the raw coal and other materials that reach the middle into a pellet. The roller skin is the heart of the briquette machine. There is a problem with the roller skin of a device that directly affects product quality. The shape of the product depends on the mold of the roller skin on the ball roller of the briquette machine. Generally, there are many shapes such as a polyhedron, goose egg shape, and spherical shape.

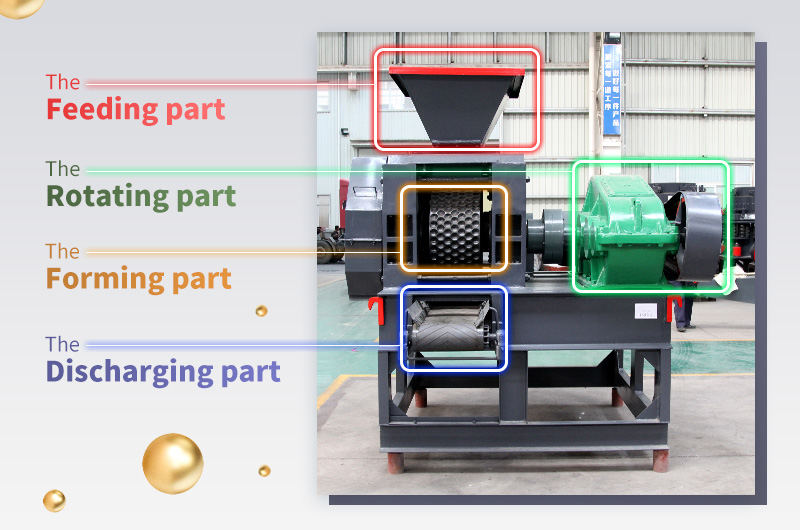

There are many types and models of the briquette machine, but the core of the briquette machine is composed of four parts: the feeding part, the rotating part, the discharging part, and the forming part. The core part of the forming part is the pressing part. Therefore, the pressure roller directly determines the quality of the machine. The roller skin has been used for a long time or the roller skin is damaged and needs to be replaced in time to avoid product failure to meet standards and waste of raw materials. For the roller skin of the briquette machine, there are a variety of materials to choose: 65Mn, high chromium alloy, 9Cr2Mo, etc., the common roller skin of Fute machinery briquette machine is made of 65Mn, 65Mn is an anti-corrosion. A good material that resists wear. The use of 65Mn forged roller skin can extend the service life of the briquette machine, prevent frequent wear and replacement, and greatly save maintenance costs. Generally, the internal organization structure is different according to the origin of the raw materials, and the roller skin material technology used will also be different. We will tailor a product plan for you.

Fute Machinery is a professional manufacturer with more than 30 years of production of the briquette machine, which is exported overseas: Malaysia, Pakistan, South Africa, Canada, and other countries. In the process of equipment production, we pay close attention to management to ensure the quality of machinery and equipment. We insist on making better quality, better products, and better services.