NEWS

The Advantages of Impact Crusher

By: Fote MachineryMarch 10th,2018

It is understood that impact crusher has always been a state of increasing demand for a long time, and this growth tendency is expect to keep going. What’s the reason that makes it welcome? It has to talk about the advantages of impact crusher.

1. Structure

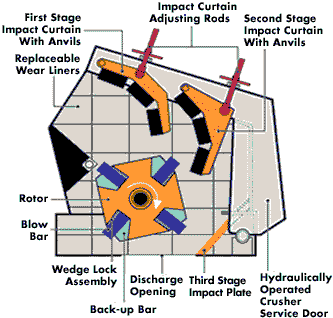

a. Impact crusher uses the multi-stage counterattack chamber, so it has enough crushing space.

b. The adjustment system of impact plate also is the over-load protection device. When the foreign materials, such as iron block and other materials that can not be broken, enter into the crushing chamber, the impact plate can rebound and bounce to make the foreign materials pass, so as to prevent the equipment from the exotic matters.

c. The hammer is fixed on the rotor, which can shorten the starting torque of crusher, and the dynamic balance performance of rotor can be controlled easily, so the disturbing force can be reduced during its working.

d. The monitoring system supervises the driving situation, and the monitoring signal can be interlocked with the main control system to ensure the crusher can be ran reliably and safely.

e. The driving system adopts the mode of “electric motor+mechanical coupling+V-type belt+crusher”, which can effectively improve the starting performance of motor to make it can be started and operated smoothly.

2. Materials’ Selection

a. Impact crusher can deal with the materials with large content of moisture, and it can effectively prevent the occurrence of blocking phenomenon without the bottom screening plate. b. The machine can use for not only soft materials, but the large hardness materials. c. It can crush the materials that the edge length is 100-500mm and below, and the compressive strength can reach up to 350MPa.

3. Working Effect

a. The advantages of impact crusher are including: big feeding port, high crushing chamber, high hardness of adaptive materials, large block size, less stone powder of finished products.

b. The gap between counterattack and hammer can be adjusted conveniently, so it can control the discharge size effectively, and has the selective crushing effect. In addition, the size of finished products is quite uniform, and the majority of them are cubic stones with better shape.

c. The crushing ratio is big, up to 40. What’s more, this equipment simplifies the crushing process. It can make the three stage crushing become two or one, which reduces the equipment cost of beneficiation factory.

d. The using lifespan of wear components is longer, and the long-term operation cost is lower.

4. Maintenance

a. It just installs 8 hammers on the rotor of impact crusher. It is very convenient to replace the hammer by using the special tools supplied by Fote, which just needs a shift time.

b. It just needs about ten minutes to replace the bottom grind sticks of grinding chamber, which greatly reduces the time and cost of overhaul and maintenance.

c. The rack of impact crusher is tripartite structure. Users can replace the hammer, impact plate, liner and other components by just opening the rear case.

Because of the advantages mentioned above on, impact crusher is very welcome in the market, and has become an indispensable stone production line and sand manufacturing process.