NEWS

Sand Dryer Introduction

By: Fote MachinerySeptember 24th,2020

1.Description of Fote Sand Dryer

Sand dryer, also known as river sand dryer, yellow sand dryer, quartz sand dryer, is a drying equipment to deal with a large number of materials. It is reliable in operation, flexible in operation, adaptable and large in handling capacity. Sand dryer is generally suitable for granular materials, especially drying sand, river sand, quartz sand drying effect is excellent. The advantages of river sand dryer are large production capacity, wide range of application, small flow resistance, large range of allowable fluctuation in operation, easy operation, etc.

2.Application of Fote Sand Dryer

Sand dryer can dry river sand, dry mixed mortar, yellow sand, cement factory slag, clay, coal gangue, mixture, fly ash, gypsum, iron powder, limestone and other raw materials, widely used in building materials, chemical industry, casting and other industries.

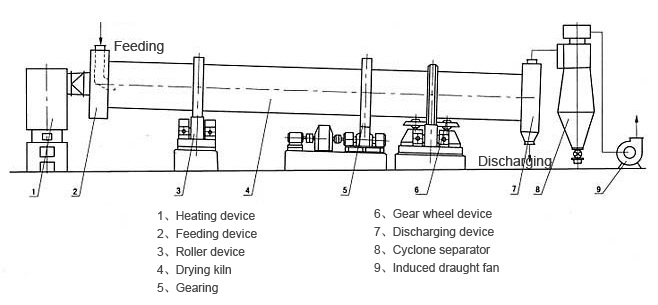

3.Structure of Fote Sand Dryer

Fote sand dryer is simple in its structure and mainly divided into 4 parts:

3.1 Drum body

The drum body is the main part of the sand drying machine. And it is equipped with the feed and discharge cases and sealing gaskets to prevent the heat from escaping.

The spiral plates are welded in the feed port, the lifting blades are equipped in the drum body, and the blocking ring is welded in the discharge port (to keep wet materials from discharging).

3.2 Support system

The support system consists of rollers, catch wheels and riding wheels, etc.

The rollers are placed around the barrel and rotate along with it.

The riding wheels support the barrel, while catch wheels prevent the barrel from displacement.

3.3 Transmission

The transmission system includes big gear, pinions, motor and gear reducer.

During the running process, the drum body is driven by motor through triangular belt, gear reducer, pinions and big gear.

3.4 Thermal systems

Fote Heavy Machinery has designed the thermal systems for customers from rainy, cold, variable-temperature countries and areas.

The thermal systems are mainly divided into two types: thermal cotton and galvanized thermal plate.

The thermal cotton is made of basalt, dolomite and binder by high-temperature melting. On the basis of insulation, the galvanized thermal plate can prevent rain, corrosion, and is suitable for rainy countries.

4.Fote Sand Dryer' Advantages

4.1 Strong wear-resistance

The main wear parts of the dryers are the drum body and the lifting plates. All of them are made of wear-resisting manganese plates, which is 3 to 4 times as the wear resistance of ordinary steel plate.

4.2 High drying efficiency

Stainless steel gaskets are used for sealing at both ports, which can efficiently prevent heat from escaping and improve the utilization of the hot gas generated by the heat source and increase the drying efficiency.

4.3 Extensive applications

The sand dryer has a drying temperature that can reach up to 800°C so that it can be used to dry bulks, particles and powders with a volume of 20 mm to 40 mm.

It can be used for various sand and stones, such as river sand, quartz sand, aggregate, frac sand and limestones.

4.4 Stable performance

The sand dryers adopt a unique internal structure, which can effectively avoid materials sticking to the inner plate, make it more adaptable to various materials.

It can reduce the degree of wear on the internal parts, making a more stable running status and high production efficiency.