NEWS

How to Prevent Pinion Damage in Ball Mill in Advance

By: Fote MachineryJuly 09th,2020

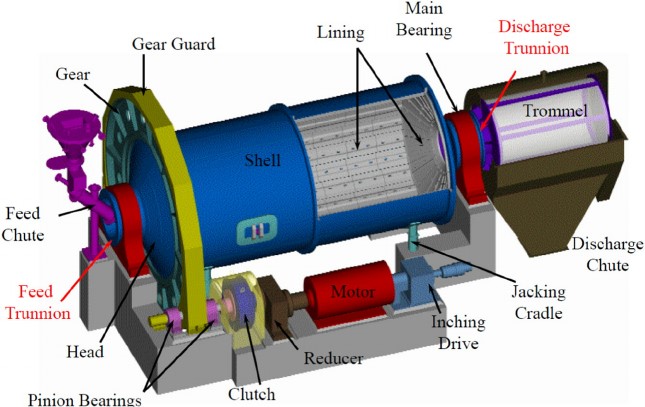

Ball mill is one of the main equipment in ore dressing operation. In the course of operation, the pinion of the ball mill will break, which will lead to insufficient and unqualified pulp in subsequent production workshops. So in the production process, how to prevent the ball mill pinion gear damage?

1. Check the current fluctuation record chart regularly

The motor current data in the ball mill workshop is displayed in the control cabinet. The pinion current change curve can be derived from the database and you can observe whether the motor current fluctuates at the rated value. When the fluctuation is in the normal rated range, the ball mill pinion is in good condition. If there is occasionally a larger instantaneous current in the data, but it does not exceed the rated current value, the data indicates that the pinion of the ball mill has a long service life, and there is aging phenomenon of parts. Therefore, the operators can carry out targeted maintenance and repair on the pinion of the ball mill according to the situation.

If the pinion gear breaks, the motor current will increase instantly, exceeding 15% of the rated value. At this time, the equipment system will be self-lock, which can effectively protect other equipment in operation.

2. Check lubrication system regularly

The lubrication system of the ball mill is forced lubrication, and the time and amount of oil filling can be clearly known from the lubrication record of the workshop. Therefore, it is necessary to check the lubrication condition of the equipment regularly, check whether the lubricating oil of the gear in the oil tank is sufficient, whether the oil quality is good, whether there are impurities, whether the nozzle is blocked and so on, and record.

3. Check the vibration degree of motor, reducer and bearing seat regularly

During the normal operation of the ball mill, the personnel on duty should check the equipment every two hours, measure and record the vibration degree of the equipment, and ensure whether the measured value of the vibration degree of the motor, reducer and bearing seat is below the specified value and whether the measured vibration degree is within the normal fluctuation range. The fluctuation degree can predict whether the pinion of ball mill is normal or not. If the fluctuation degree exceeds the fixed value, it is likely that the pinion has worn.

When the surface of the pinion of the ball mill is found to be worn, it can be manually polished if it is not serious, so as to reduce the surface roughness of the gear and ensure the normal operation of the pinion; If badly worn or broken, the pinion needs to be replaced.

4. Check the operating temperature regularly

The operating temperature of the ball mill is set by the temperature specified in the equipment manual. The setting temperature of the bearing on both sides of the motor, reducer and pinion are different, and the temperature is also controlled by the automatic system, which has a chain effect.

Under the long-term operation of the ball mill, if the pinion wears away, the operating temperature of the equipment will increase; if the pinion wears away seriously or breaks, the operating temperature of the ball mill will rise sharply, leading to stop of the ball mill. Therefore, the equipment temperature can be observedto check whether there is a fault in the ball mill pinion (ball mill operating temperature range of 50 ~ 65°C).

The above four daily inspection records can not only check the ball mill small gear fault, but also check the large gear bearing and other components whether there is a fault, so the ball mill daily spot inspection, regular maintenance is essential.

FTM®Ball Mill has high performance and reliable quality, which exported to 200+ countries. Welcome to consult with.