NEWS

How to Choose the Right Rotary Dryer

By: Fote MachineryMay 30th,2022

Rotary dryer is a kind of drying equipment, which is widely used in mining equipment. The application range of rotary dryer includes slag, cinder, lignite, slag, sand, limestone, clay and chicken manure, sawdust, etc.

The barrel of rotary dryer is a horizontal rotary cylinder, and there are various kinds of coping plates with different angles welded from front to back, and different types of refractory bricks are set inside the rotary kiln according to the demand, and there is a door ring and a spiral coping plate at the feeding end to prevent the material from falling back, which is a reasonable structure. At the same time, the rotary dryer is easy to operate and has the advantages of high output, low energy consumption and convenient operation.

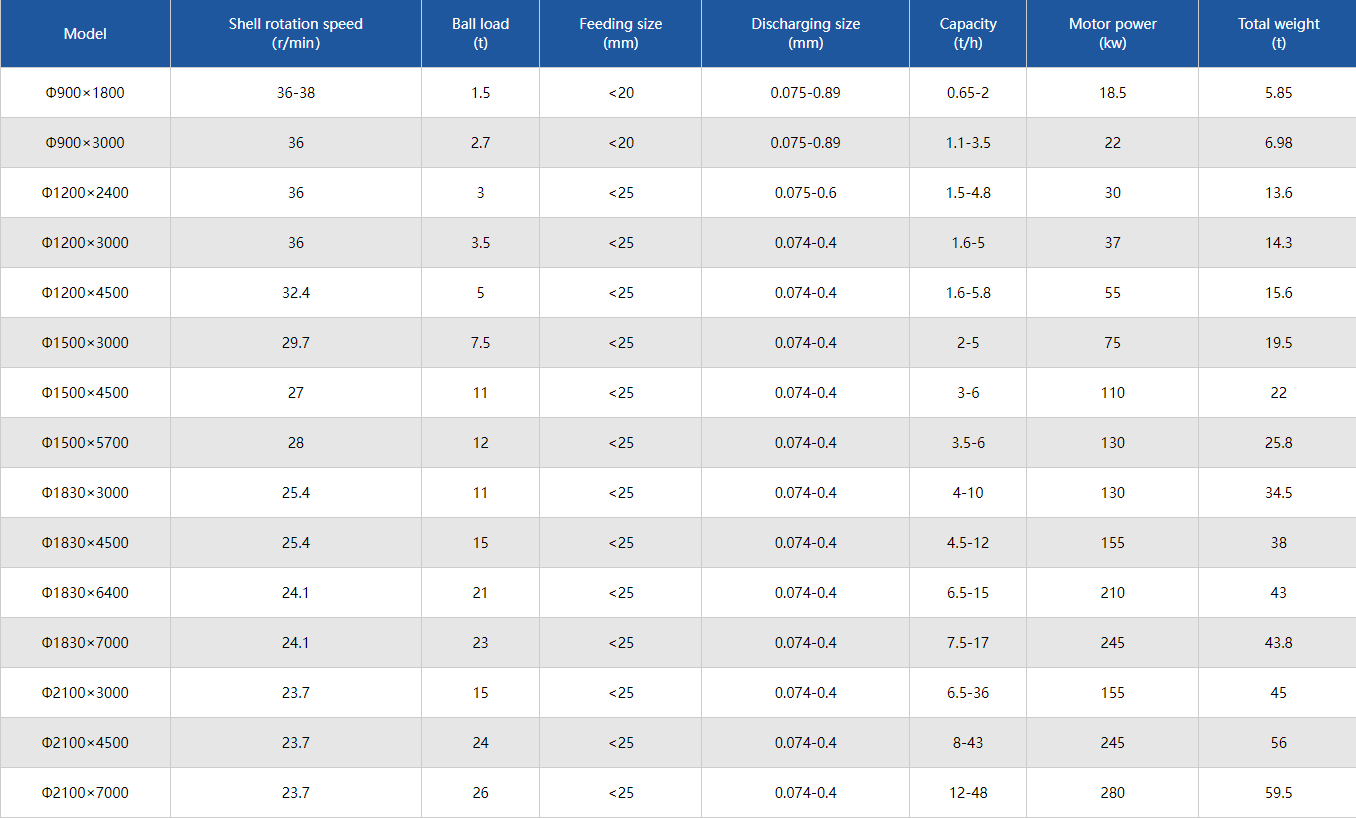

There are different model specifications of rotary dryer. To save investment, reduce operation cost, ensure product quality and get the maximum economic benefit, we should choose the specification of dryer reasonably.

The selection of dryer should mainly consider the characteristics of the dried materials and the requirements of the moisture content of the dried products, etc. The ideal selection of dryer must be based on the user's own needs and material factors in order to find the most suitable model for their materials.

The general principles of drying equipment selection as follow:

1. Make the material drying experiments before selection. In-depth knowledge of the drying units already in use for similar materials is often helpful for proper selection.

2. Preferably choose the drying device with simple structure, sufficient supply of spare parts, high reliability and long service life.

3. Drying equipment must first be applicable to specific materials and meet the basic use requirements of material drying, including the ability to handle materials well and meet the basic requirements of handling capacity, water removal, product quality, etc.

4. Consider the operating cost. Equipment depreciation, energy consumption, labor costs, maintenance costs, spare parts costs and other operating costs should be as low as possible.

5. Choose the machine with high drying rate. Only in terms of drying rate, convection drying, the material is highly dispersed in the hot air, the critical moisture content is low, the drying speed is fast, and the same convection drying, drying methods are different critical moisture content is also different, so the drying rate is also different.

6. Meets the requirements of environmental protection, good working conditions and high safety.

The rotary dryers produced by Henan Fote Mining Machinery Co., Ltd are designed around the specific needs of our customers. For more information about our rotary dryers or services, please contact us today!