Brief Introduction

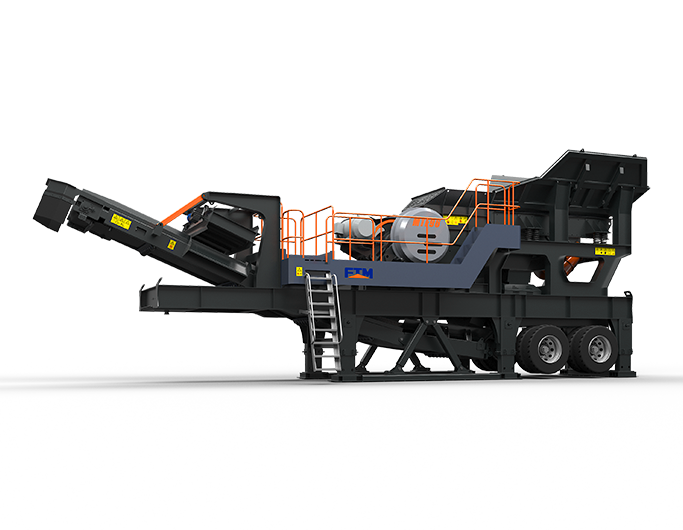

In practical production, wheeled mobile crushing stations are widely used in numerous industries such as mining, metallurgy, construction materials, highways, railways, water conservancy, and chemical industries. They are used for tasks such as mobile crushing operations in construction waste and mining areas, making them essential equipment in many ore and stone yards. Depending on the characteristics of the processed raw materials, scale, and finished product requirements, different configurations can be adopted. The main equipment configurations include jaw crusher, impact crusher, cone crusher, vibrating screen, sand making machine, heavy hammer crusher, fine crusher, and other equipment. Therefore, there are options or complete sets of coarse crushing mobile stations, medium-fine crushing mobile stations, sand making mobile stations, and screening mobile stations, which can be quickly assembled into a cohesive production line, making the entire production line "mobile".